PUMPS, VALVES AND COMPRESSORS MANUFACTURING

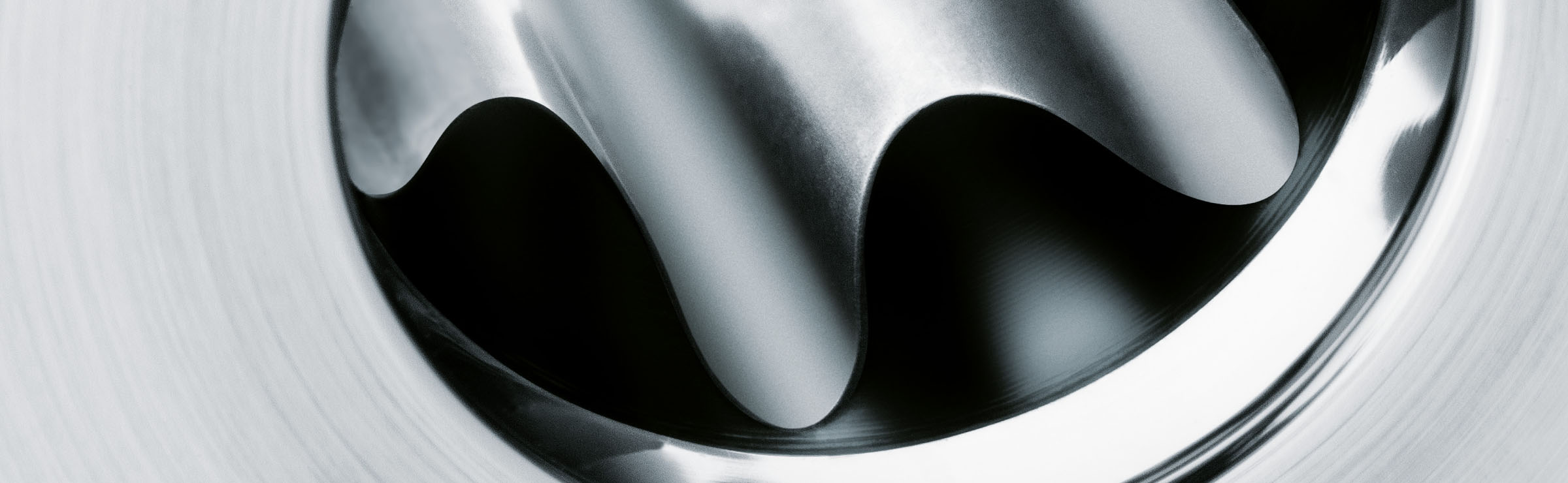

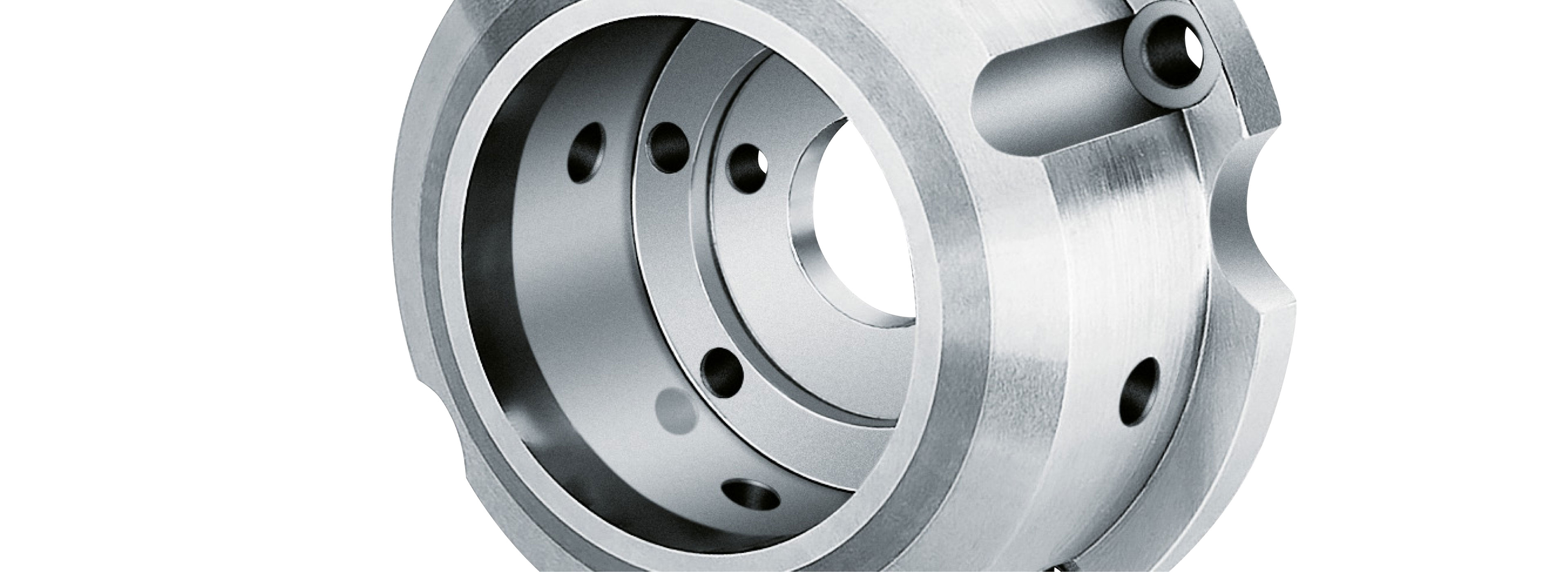

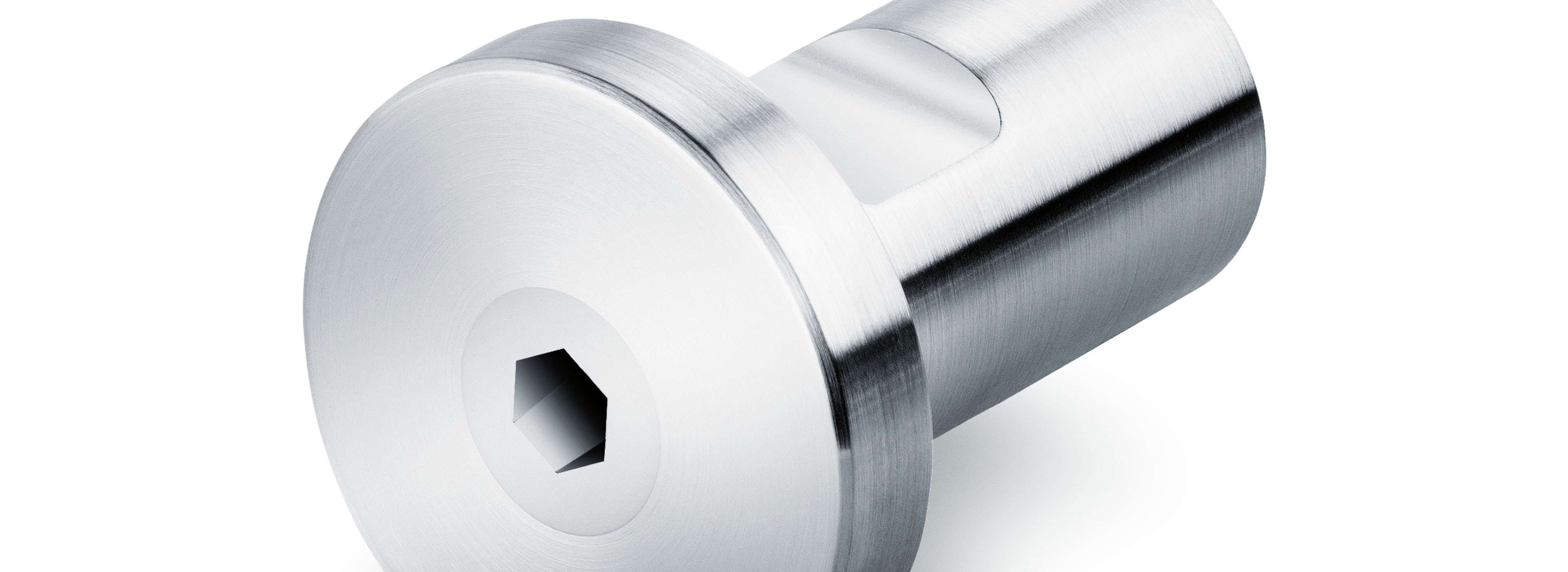

The targeted application of tungsten carbide greatly increases the EFFICIENCY OF PRODUCTION. Especially in pumps, valves and fittings manufacturing and general sealing technology, parts and components made from tungsten carbide create decisive COMPETITIVE ADVANTAGES. For applications requiring corrosion resistance, DURIT additionally offers a broad range of tungsten carbide grades with chrome/nickel-binders.

Discover products:

Pumps, Valves, Compressors » »

OIL, GAS, PETROCHEMICAL

Tungsten carbide has been used in flow control technology for many years. The reason: ONSHORE JUST AS OFFSHORE we often find extreme conditions. Moisture, sand and abrasive solids cause enormous wear – not only downstream, but in all stages of upstream processing operations following extraction. For years DURIT has led the way in areas like offshore technology, exploration technology, drilling technology, power generation and environmental protection – industries in which tungsten carbide is becoming more and more important.

Discover products:

Oil, Gas, Petrochemical » »

CHEMICAL AND PHARMACEUTICAL

Achieve more with higher durability: large-batch production, such as technical tableting in pharmaceutical and chemical industries causes high wear and requires WEAR-RESISTANT POWDER-COMPACTING TOOLS. The use of tungsten carbide offers decisive advantages. Service lives can be increased up to 50 times compared to steel tools. Downtime is considerably reduced – it’s almost like legal doping for production.

Discover products:

Crushing, Milling, Pelletizing, Recycling » »

Conveying, Mixing, Extruding » »

Powder pressing and tableting » »

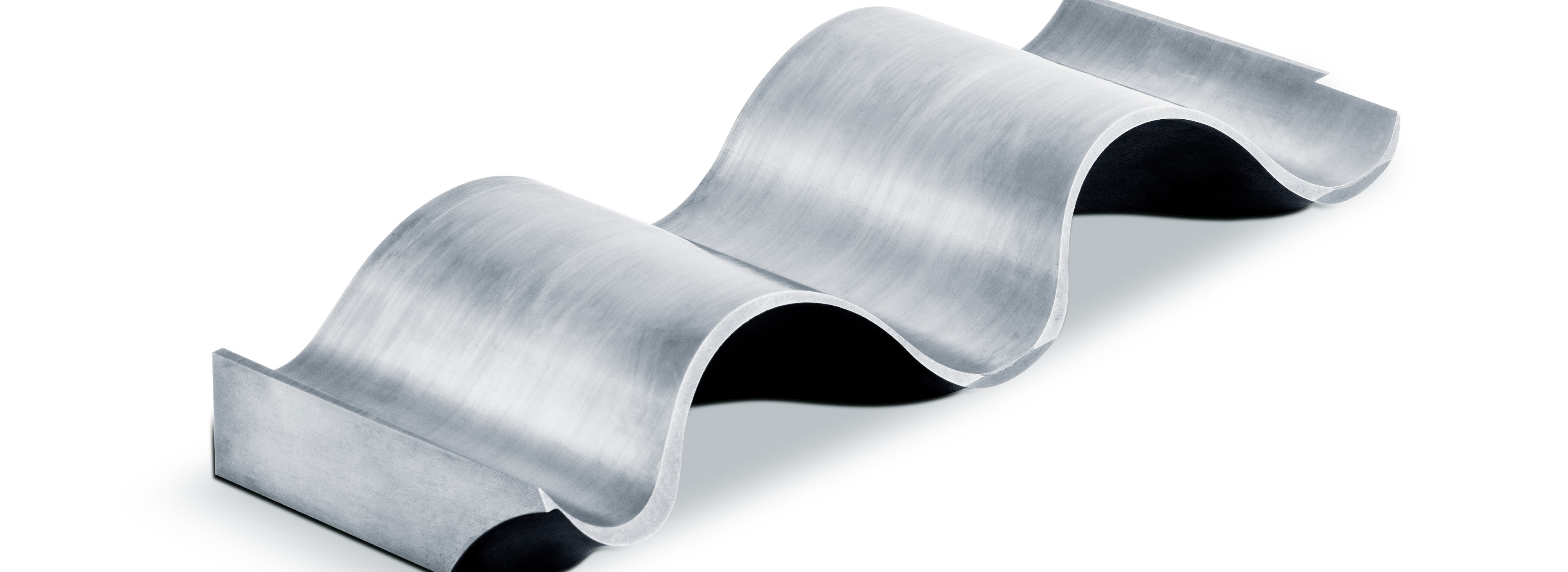

Sheet metal and metal packaging industry

Manufacturers in the sheet metal processing industry have been under considerable pressure to reduce costs for years. They are forced to produce increasingly complex products using a large variety of technologies at low cost. The use of tungsten carbide can SIGNIFICANTLY INCREASE THE RATE OF ECONOMIC EFFICIENCY. Typical applications where DURIT already makes a difference: general sheet metal containers, cans, lids, transformer sheets and more.

Discover products:

Sheet metal forming and metal packaging » »

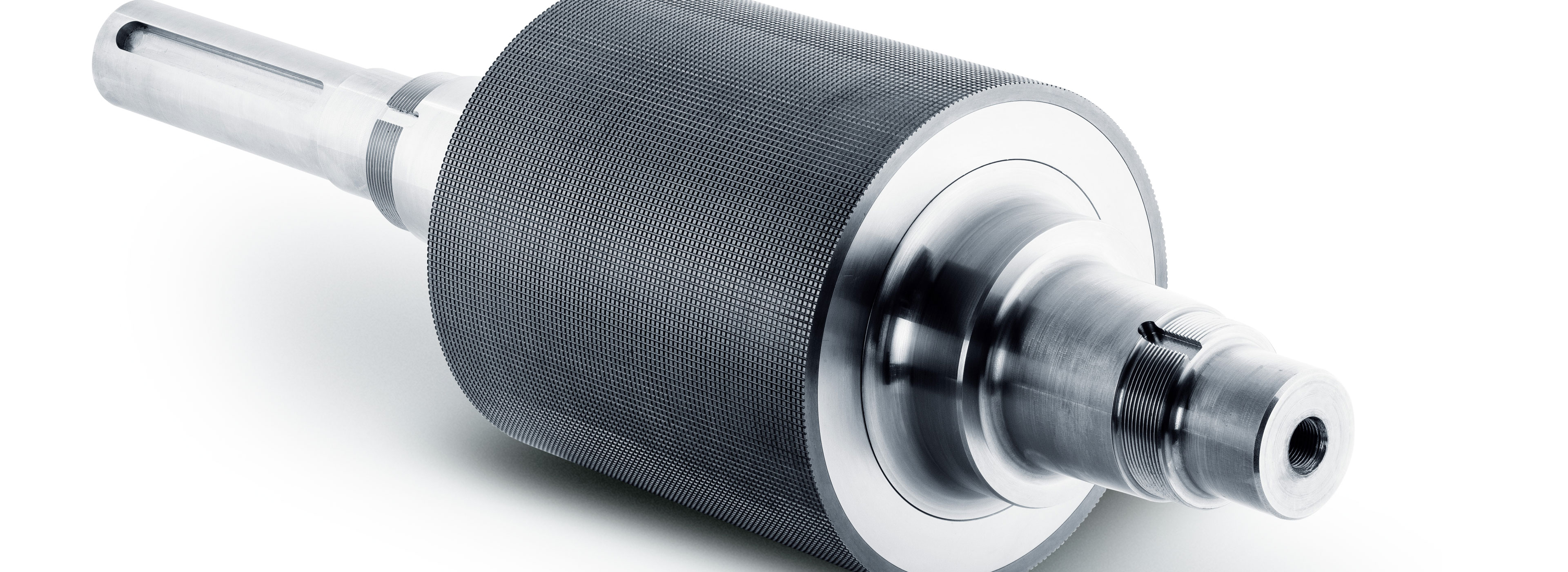

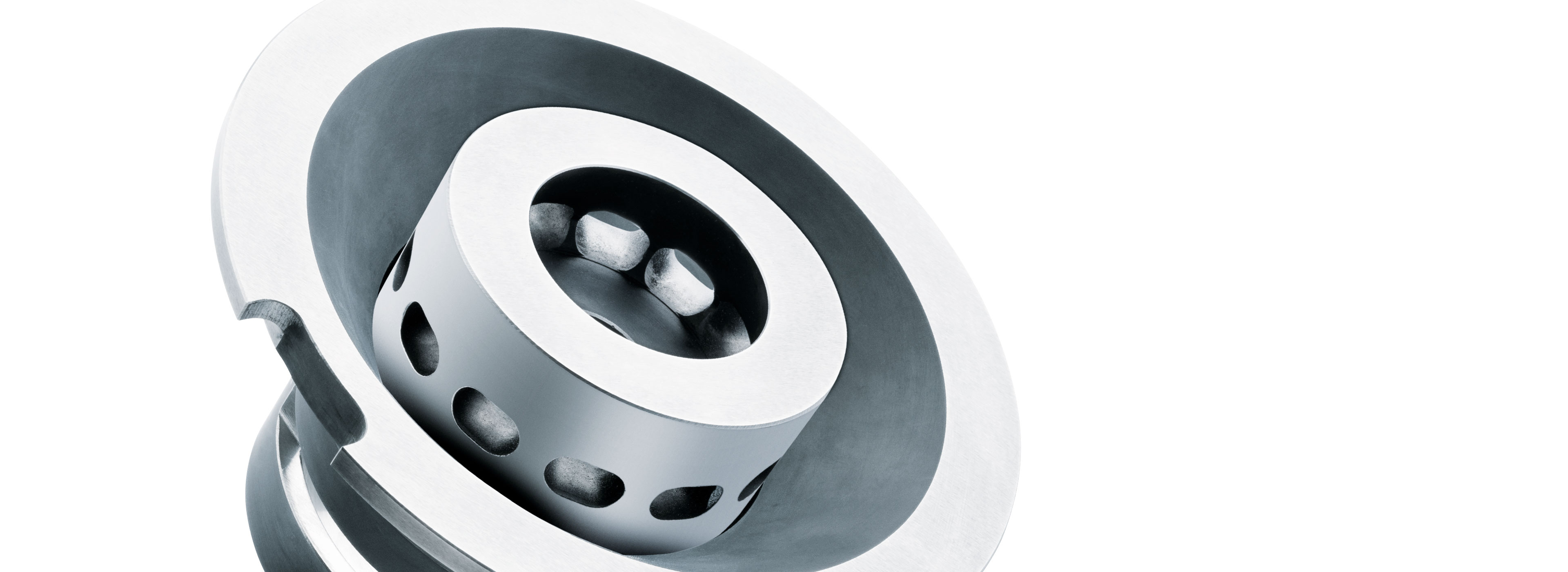

PLANT AND MECHANICAL ENGINEERING

There are increasingly higher demands on plants and machines when it comes to economic efficiency, output quantity and service life. Installed parts and components have to meet strict requirements for HARDNESS, TOUGHNESS AND DIMENSIONAL ACCURACY. This is exactly what carbide delivers – especially in large part processing, roll barrel production, dynamic balancing and other areas.

Discover products:

Constructional parts » »

Machine parts » »

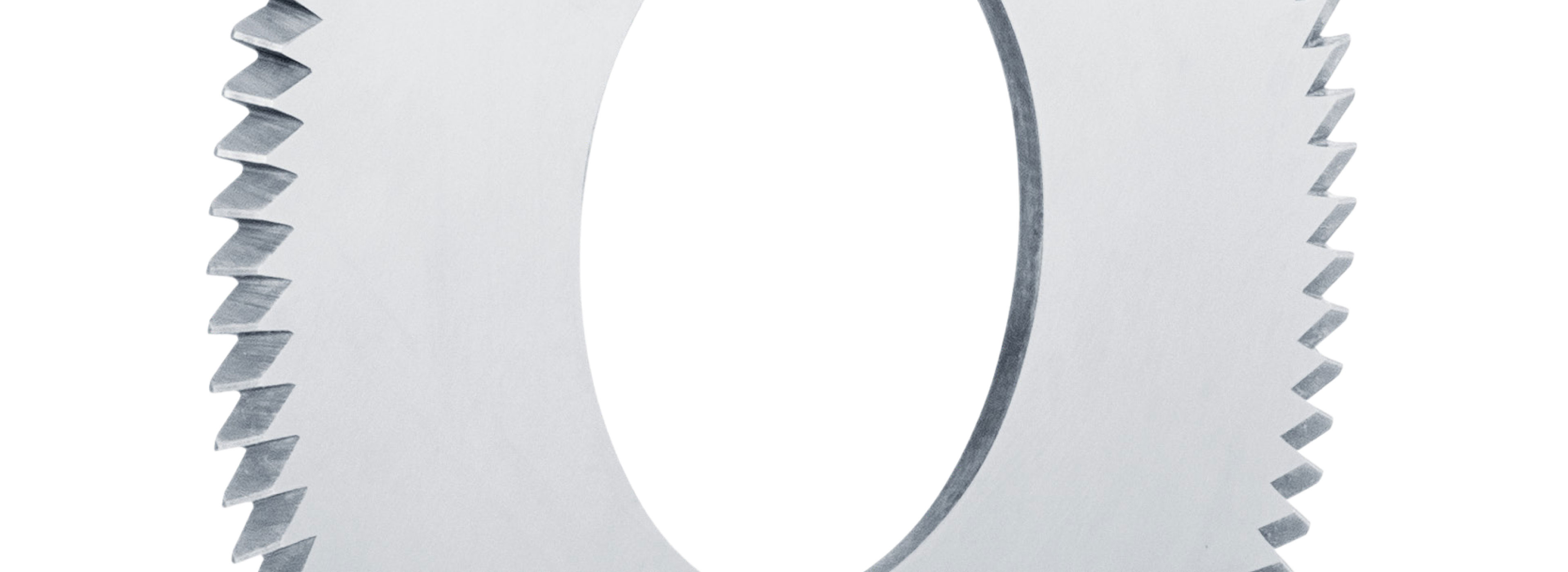

PAPER PROCESSING

Tungsten carbide ensures cutting-edge results and INCREASED PRODUCTIVITY when processing paper, cardboard, and special pulp products like tissues or other products related to the hygiene industry. Compared to tempered tool steel, tungsten carbide features a SIGNIFICANTLY HIGHER PRESSURE AND WEAR RESISTANCE. It increases the cutting edge stability and therefore ensures better dimensional accuracy. Carbide achieves outstanding results - for the perfect cut.

Discover products:

Cutting tools » »

METAL SHAPING

Screws, rivets, springs, tubes: In metal shaping it’s one after another. Production demands are constantly increasing. Here, CARBIDE RELIABLY WITHSTANDS EXTREME PRESSURES, TEMPERATURES AND ABRASIVE MEDIA. By the way: The construction and manufacturing of cold heading tools for the production of fasteners require a lot of experience. In cooperation with our customers we develop unique and highly specific tool designs.

Discover products:

Sheet metal forming and metal packaging » »

Drawing dies » »

POWDER PROCESSING

Powders and granules are processed in all industries. Due to automation and fine-tuning of production processes more and more attention is focused on economic efficiency. When it comes to mixing, milling and crushing – for example in processes in the paint and coating industries – TUNGSTEN CARBIDE’S HIGH WEAR RESISTANCE GREATLY IMPROVES PRODUCTIVITY. For a long time to come.

Discover products:

Crushing, Milling, Pelletizing, Recycling » »

Conveying, Mixing, Extruding » »

Powder pressing and tableting » »

RECYCLING AND SHREDDING TECHNOLOGY

Crushing recyclable products or materials puts EXTREME DEMANDS on tools and parts. In these applications tungsten carbide features a much HIGHER BREAK RESISTANCE than ceramics and a much HIGHER WEAR AND PRESSURE RESISTANCE than steel or other materials. That is why tungsten carbide gains in importance especially in the fast-growing recycling industry. Particularly suitable for milling and crushing technologies, it makes a significant contribution to increase productivity.

Discover products:

Crushing, Milling, Pelletizing, Recycling » »

Cutting tools » »

REFRACTORY INDUSTRY

Powder-compressing tools made of tungsten carbide have proven incredibly successful in processing high-wear media. The careful selection of carbide grades has an enormous impact on performance and service life of tools. PRESSING DIES, MOLDS, ARBORS AND LININGS for the refractory industry are plated with a specific carbide that impresses with extremely high wear and pressure resistance and outstanding hardness. They are characterized by durable DIMENSIONAL ACCURACY AND SURFACE QUALITY.

Discover products:

Powder pressing and tableting » »

Crushing, Milling, Pelletizing, Recycling » »

AUTOMOTIVE

Quality comes first in the automotive industry. 100% of all parts produced are inspected. There is zero tolerance for errors. Even service partners or suppliers have to have the right tools that cannot fail. DURIT is particularly EXPERIENCED IN DEVELOPING AND PRODUCING tools for the automotive industry and is the top tungsten carbide partner to the automotive industry.

Discover products:

Machine parts » »

Sheet metal forming and metal packaging » »

Drawing dies » »

CONCRETE ROOFING INDUSTRY

Components and tools made of tungsten carbide are used for PREVENTING EARLY WEAR in numerous industries. This includes the roof tile industry and the concrete roofing industry. DURIT has excellent references and long-standing partnerships in this sector. Beyond this special segment, we develop and produce numerous tungsten carbide grades and specialized tools required in building, mining, and tunnel construction.

Discover products:

Conveying, Mixing, Extruding » »

BLASTING AND SURFACE TECHNOLOGY

Surface finishing, surface cleaning and more: processing abrasive media puts very particular demands on the quality of tools and components – tungsten carbide meets them. DURIT offers individualized solutions ensuring MAXIMUM QUALITY AND EFFICIENCY and providing decisive competitive advantages. Our customers tell us their requirements for a part, tool or component. Our experts find the most economical and technically appropriate solution.

Discover products:

Blasting and Surface technology » »

PLASTICS

The plastics industry benefits from numerous wear-resistant tungsten carbide products made by DURIT as well. Their extraordinary hardness IMPROVES SERVICE LIVES of thermally and mechanically strained components. Our special grades offer – when requested – HIGH THERMAL CONDUCTIVITY AND CORROSION RESISTANCE. That means: our experts have a solution for virtually any granulating process – from strand granulation to under-water granulation.

Discover products:

Constructional parts » »

Conveying, Mixing, Extruding » »

FOOD PROCESSING

Tungsten carbide can safely be used in the food industry and offers many advantages. Wear-resistant solutions by DURIT are characterized by HIGH CORROSION RESISTANCE. This makes cleaning of machine parts with aggressive solvents possible – just as with stainless steel. Established applications of machine parts made of solid tungsten carbide in the food industry include stirring paddles, blades, whisks, nozzles, grinder parts, separator rings, homogenizing pins and more.

Discover products:

Cutting tools » »

Crushing, Milling, Pelletizing, Recycling » »

Conveying, Mixing, Extruding » »

Sheet metal forming and metal packaging » »

Bending and forming technology » »