Das Durit Service-Center.

Mehrwert als Service. Leidenschaft als Werkzeug.

Schnelle Kommunikation und kurze Reaktionszeiten sind uns wichtig. Als zukunftsweisendes Unternehmen vereinen wir deshalb Verwaltung, technische Abteilungen und Service unter einem Dach. Der Vorteil für unsere Kunden: Wir können für Sie Rohlinge und Bauteile vor Ort bearbeiten und sehr kurze Lieferzeiten realisieren.

Mit schnelleren Reaktionszeiten sind wir in der Lage, sofort spürbaren Mehrwert zu schaffen.

Dies spiegelt sich auch in der Funktionalität unseres Gebäudes wider. Zeitgemäß ausgestattete Büros, lichtdurchflutete Konferenzräume und offene Meeting-Points unterstützen eine Kultur des partnerschaftlichen Miteinanders – konsequent ausgerichtet auf die Bedürfnisse unserer Kunden.

Der DuritNachschleifservice.

schnell und unkompliziert.

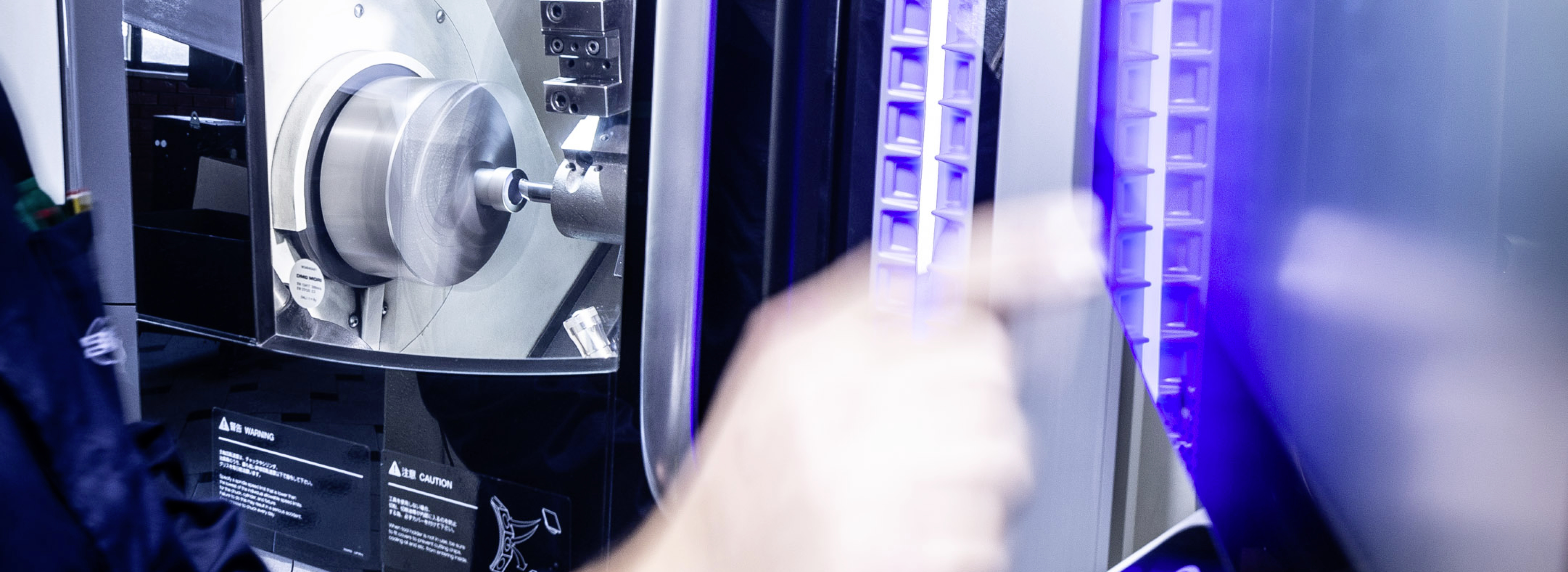

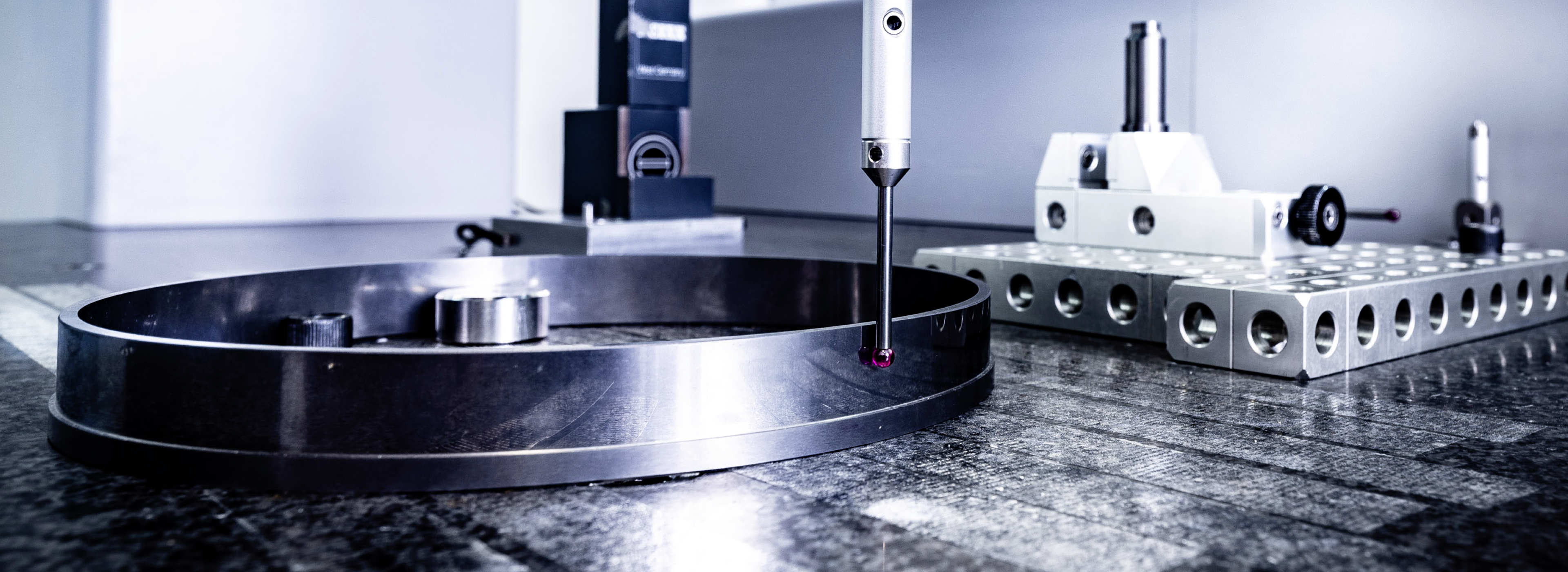

metallbearbeitung in der unternehmenszentrale.

Mit unserem Service-Center, erhöhten Lagerkapazitäten und einer professionellen Logistik-Station erfüllen wir die Anforderungen der Zukunft –

für uns ist das gelebteKundennähe. Kleinere Reparaturen können wir dadurch schneller für Sie erledigen. Verschleißteile werden kürzester Zeit optimiert und innerhalb unseresNachschleifservicesschnell und unkompliziert wieder fit für härtere Anforderungen gemacht.

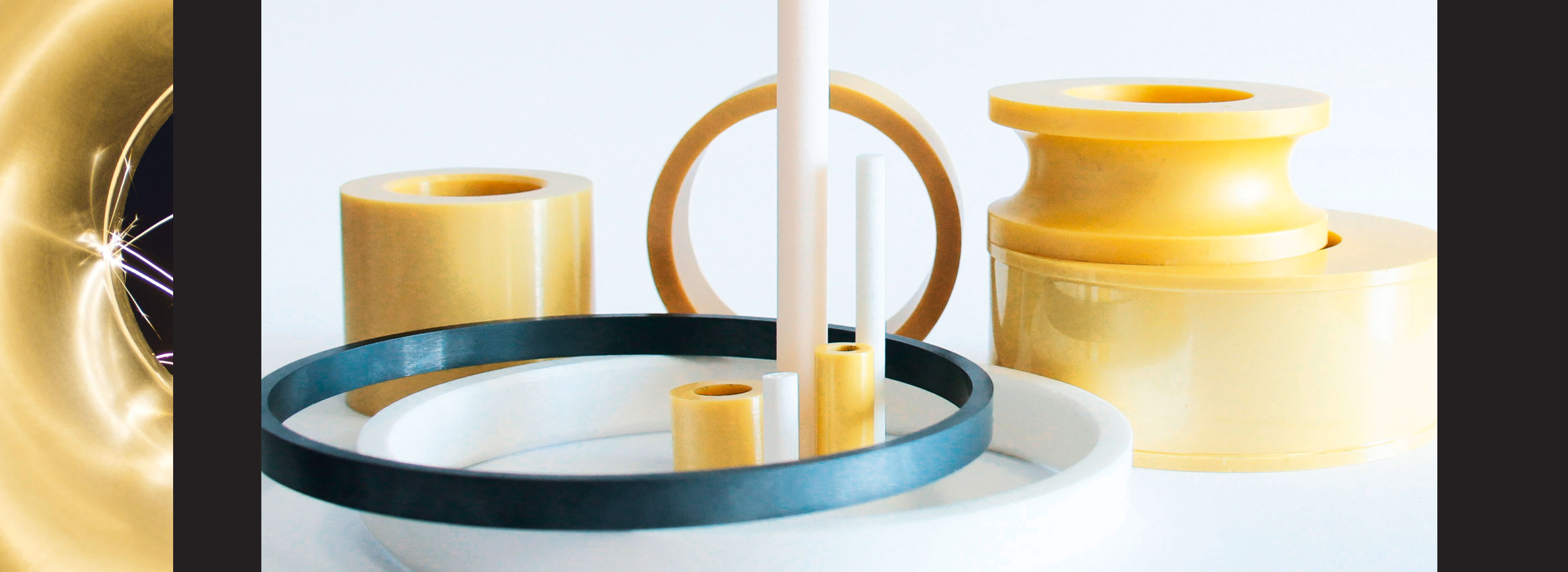

Spezial-Werkstoffe

» Verschleißkompetenz weiter gedacht

Wir beschäftigen uns nicht nur mit Hartmetall und Beschichtungen. Wir setzen uns auch mit weiteren verschleißoptimierenden MATERIALIEN UND WERKSTOFFEN auseinander.

» Keramik – ein Werkstoff für besondere Ansprüche.

Keramische Werkstoffe zeichnen sich durch GERINGE DICHTE, HOHE HÄRTE SOWIE SEHR GUTE TEMPERATUR UND KORROSIONSBESTÄNDIGKEITaus. In zahlreichen industriellen Herstellungsprozessen und Produktbereichen verbessern sie die Funktionalität der Komponenten und Endprodukte.

Hochleistungskeramiken von DURIT sind aufgrund ihrer Beschaffenheit und Eigenschaften VIELFÄLTIG EINSETZBAR.

» hohe mechanische Festigkeit

» sehr gute elektrische Isolation

» gute Gleiteigenschaften

» thermoschockbeständig

» gute Risszähigkeit

» sehr niedrige Wärmeausdehnung

» sehr gute Bruchzähigkeit

» niedrige Wärmeleitfähigkeit

» gute Korrosionsbeständigkeit

| MATERIAL | Dichte Density (g/cm3) | Härte Hardness (HV10) | Druckfestigkeit Compressive strength (MPa) | E-Modul Young’s modulus (GPa) | Wärmeleitfähigkeit Thermal conductivity 20 °C (m/mK) | ||

|---|---|---|---|---|---|---|---|

| Aluminiumoxid (Al2O3) | 3,9 | 1900 | 2400 | 370 | 30 | ||

| Siliziumnitrid (Si3N4) | 3,2 | 1750 | 3000 | 300 | 21 | ||

| Zirkonoxid (ZrO2-MgO) | 5,6 | 1250 | 1700 | 205 | 2,0 | ||

| Zirkonoxid (ZrO2-Y2O3) | 6,02 | 1350 | 2000 | 180 | 3,0 |

Die Durit Konstruktionund Entwicklung.

unsere kunden kommen weiter.

auch, weil wir weiter denken.

Die Trends und Entwicklungen auf dem Verschleißteilsektor erfordern eine stetigeVerbesserung der Werkzeug- und Bauteilqualität.

Nur so kann die Wirtschaftlichkeit der Produktion dauerhaft gewährleistet werden.

In diesem Sinne ist DURIT Hartmetall ein erfahrener und zuverlässiger Partner für die Entwicklung, Konstruktion und Fertigung vonSonderwerkzeugen auf Kundenanforderung.

Werden ganz individuelle Anforderungen hinsichtlich derVerschleißfestigkeitgestellt oder erfordert ein Produktionsprozess einen Werkzeugwerkstoff mit erhöhterDruckfestigkeit, sind wir der richtige Ansprechpartner, denn wir setzen uns intensiv mit der Herausforderung Verschleiß zu minimieren auseinander. Das spezifische Eigenschaftsprofil unserer Hochleistungswerkstoffe eröffnet dabei oftmals neue Potenziale.

» Unsere CAD-gestützte Konstruktionsabteilung entwickelt individuelle Lösungen für Ihre Problemstellung. Sprechen Sie uns an!

Die Durit Workshops.

wissen teilen.

arbeitsprozesse optimieren.

Technische Workshops undfundierte Workshopsfür Produktionsleiter, Ingenieure und Maschinenbediener bedeuten einen positiven Einfluss auf die Wirtschaftlichkeit von Produktionsprozessen.

Das bedeutet: Uns ist nicht die Aus- und Weiterbildung unserer eigenen Mitarbeiter wichtig, sondern auch die Entwicklung der technischen Kompetenzen der Mitarbeiter unserer Kunden. Mit Hartmetall-WorkShops und spezifischen Produktschulungen schaffen wir eine wesentliche Voraussetzung für Ihren Erfolg!

Aus der Praxis für die Praxis.

Auf Wunsch veranstalten wir Workshops und Schulungen zum Thema Hartmetall, Beschichtungen und Verschleiß. Diese finden in kleinen Gruppen statt.

Von Profis für Profis.

Experten aus dem Bereich Hartmetall und Verschleißschutz weisen Sie intensiv auf Ihr Produkt ein. Auch danach steht Ihnen das DURIT Team bei allen Fragen gerne fachmännisch zur Seite.