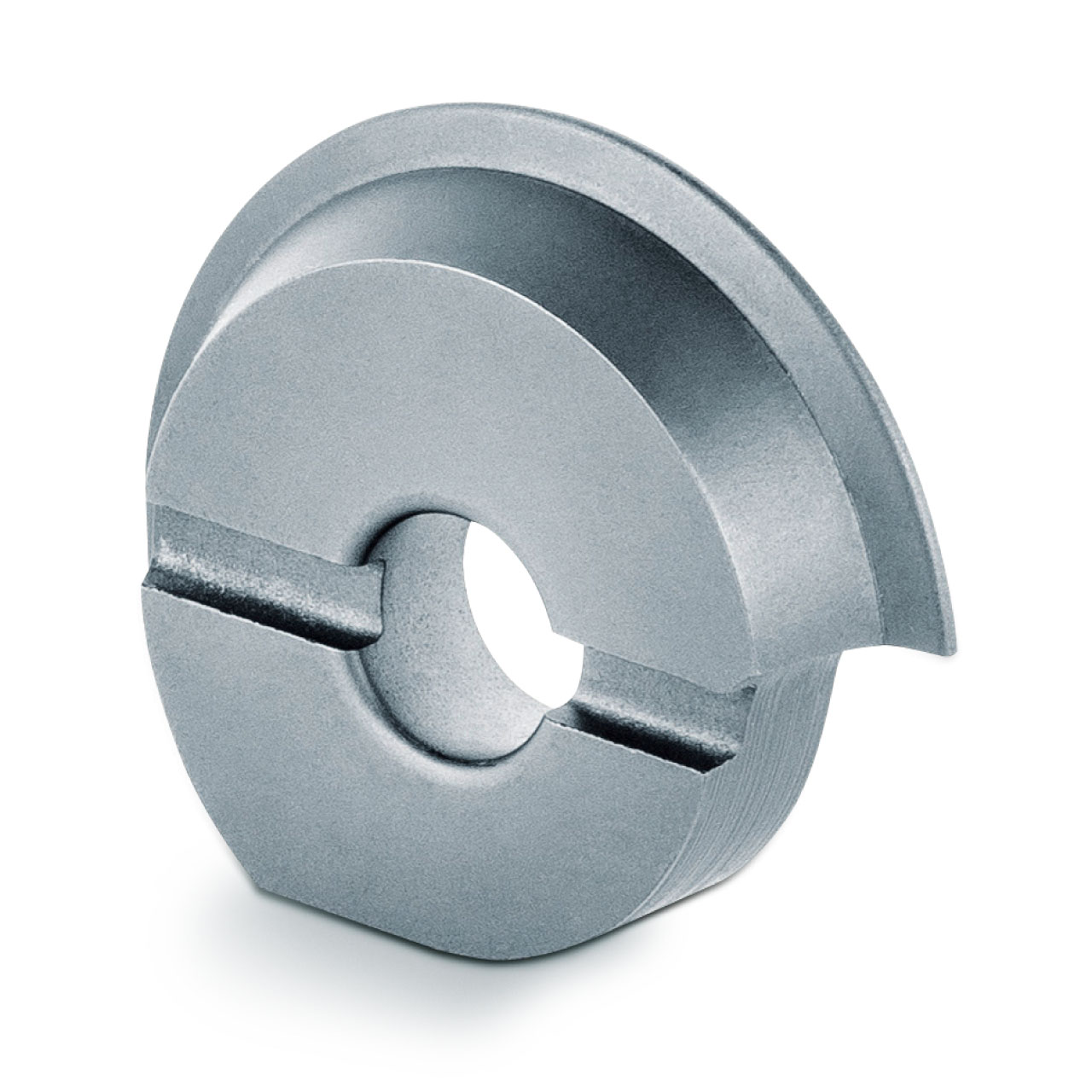

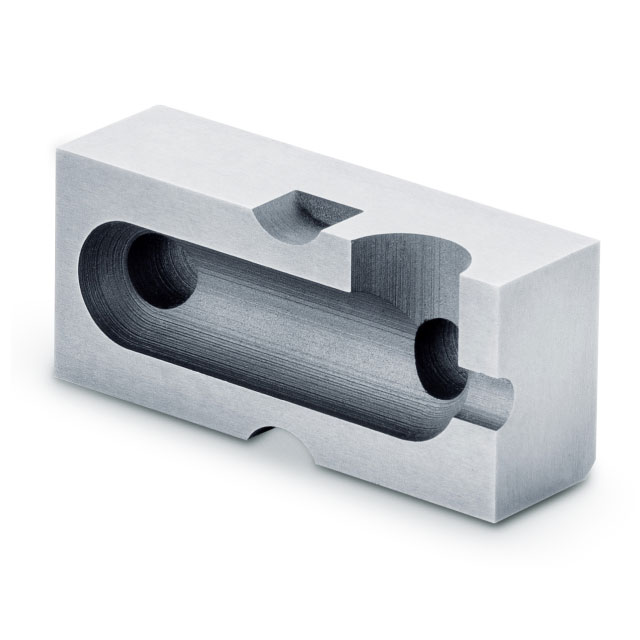

BLANKS

True in form.Dimensional accuracy.Consistent Quality.

products »

Shaped components, cores, rings, plates, strips, blades, erosion blocks, rods, nozzles, nipples

typical applications »

Plant construction and mechanical engineering; tool, die and mold making; shaping, drawing and sizing tools and more

Accelerators

Special shearing-blades

Grip plates

CLOSER TO THE FINAL PRODUCT

Blanks by DURIT have a very low wear tolerance,

optimizing further processing.

Formstamps powder press tools

Accelerators

HM-Insert firing or connection boreholes

PRECISION WORK.

We manufacture semi-finished products as

well as blanks from customer

drawings with maximum precision.

Drivers

Stamp blank

Hook steel