CONVEYING, MIXING, EXTRUSION

Consistent.Lasting.Dimensional stability.

products »

Extruder screws, augers, mixer paddles, linings, sleeves, perforated and multi-hole plates, screw segments, shaping rolls, slippers, dies

typical applications »

Technical ceramics, paints and coatings, concrete industry for roof tiles, food industry, composites and more

![[Translate to English:] Förderschnecke - Fördern Mischen Extrudieren DURIT [Translate to English:] Förderschnecke - Fördern Mischen Extrudieren DURIT](/fileadmin/user_upload/durit/Produkte/Foerdern_Mischen_Extrudieren/Foerderschnecke-Foerdern-Mischen-Extrudieren-DURIT.jpg)

Conveying scroll

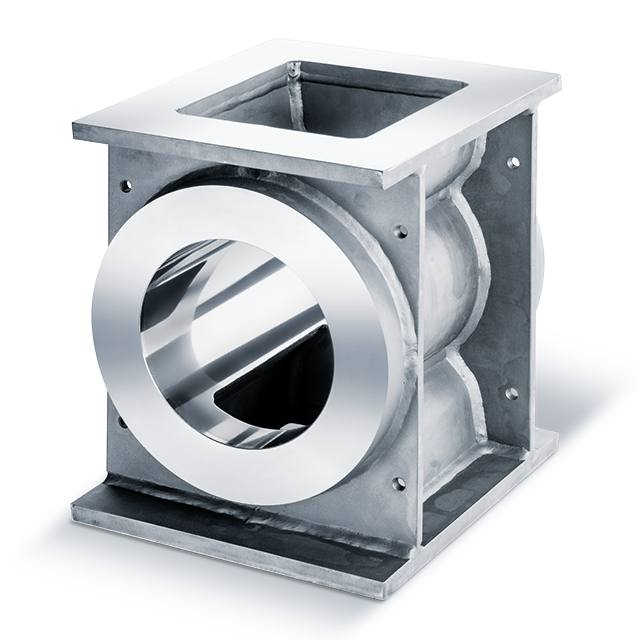

Valve housing

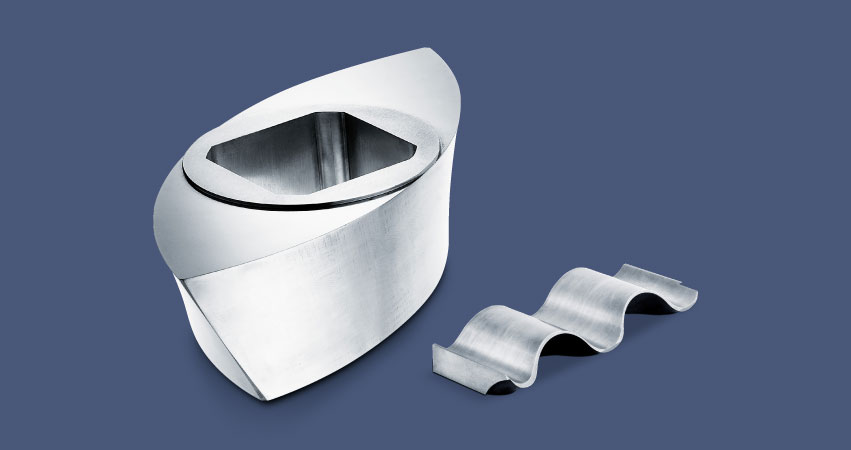

End slipper

Pointed head screw

Extruder screw segment

Profile roller

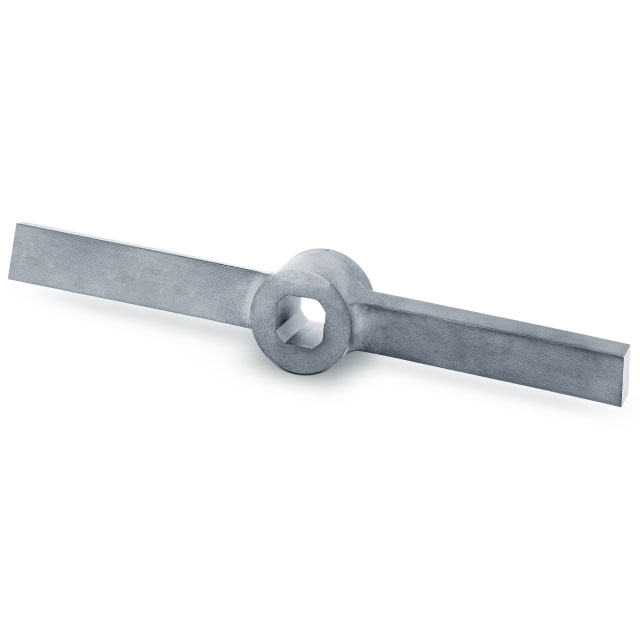

Mixer paddle

OPTIMAL PERFORMANCE.

Carbide-coated or solid carbide – our design is optimized for your application and manufactured with your specific requirements in mind.

SHOWING STRENGTH.

Carbide lasts a lot longer when processing, mixing and extruding abrasive, high-wear solids and dispersions.

Mixer insert

PVD Coating HardTiL®

Profile roller

Mouthpiece

IMPROVING RESULTS.

Components and tools by DURIT Hartmetall are specifically targeted and used successfully to prevent premature wear and tear.

Mixer arm