Performance and longevityperfectly balanced.

The types of products we can improve by applying thermal coatings, laser cladding, PVD or CVD coatings are virtually infinite. Our coatings to improve wear -resistance exemplify the highest degree of technological innovation and result in drastically increased lifetime of parts, tools and components.

REDUCED

» Abrasion

» Erosion

» Friction

INCREASED

» Resilience (Wear and Corrosion)

IMPROVED

» Conductivity (electrical, thermal)

» Insulation (thermal)

CREATED

» Bio Compatibility

thermal spray coatings:

More effectiveagainst wear

DURIT Thermal coatings are often the only option to drastically improve operational performance. For the best results we carefully analyze wear tracks, patterns and possible causes of failure, including all available parameters, such as temperature, pressure, adjacent parts and the processed medium. Our latest flame spray method delivers unique and significantly improved application-specific properties – especially when it comes to durability and longevity.

THERMAL SPRAY PROCESSES

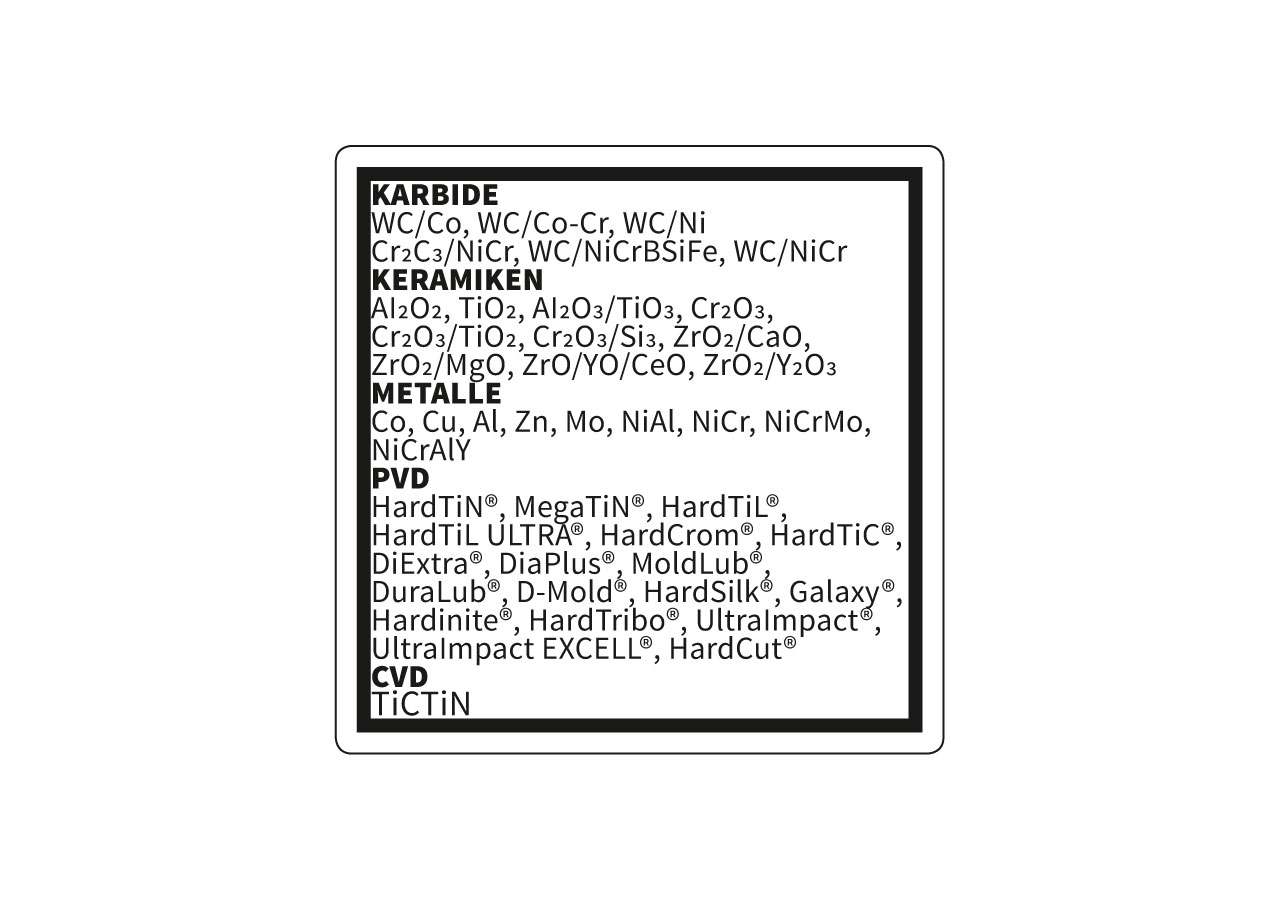

COATING MATERIALS

(Additional coating materials by request)APS

Atmospheric Plasma Spraying» More » »

CERAMICS

Al2O3TiO2Al2O3/TiO2Cr2O3Cr2O3/TiO2Cr2O3/SiOZrO2/CaOZrO2/MgOZrO/YO/CeOZrO2/Y2O3HVOF

High Velocity Oxi-Fuel

HVOF-Flame Spraying is a high-velocity process, usually applying a carbide or metal layer coating, which allows our experts to create densely sealed surfaces.

Properties

Ø adhesive tensile strength: > 80 MPa

Ø porosity: 0,5 % to 1 %

Ø layer thickness: 100 to 500 µm

Advantages

» low thermal stress of the base material

» high resistance to linear stress

» possible to coat any material as well as partial coating

» high density of sprayed layer

» thin layers with high dimensional accuracy

APS

Atmospheric Plasma Spraying

The most flexible of all thermal spray processes produces enough energy to melt any material and allows superior handling to achieve – usually with ceramics – optimal layer thickness and surface characteristics.

Properties

Ø adhesive tensile strength: 20 to 50 MPa

Ø porosity: 4 % to 8 %

Ø layer thickness: 200 to 1.000 µm

Advantages

» broad range of materials

» minimal heat transfer into the part

» superior control over layer thickness and surface characteristics

» possible to coat small inner bores

» improvement of thermal or electrical insulation

EAWS

Electric Arc Wire Spraying

This process allows massively increased protection against wear, improved corrosion resistance, thermal insulation, electrical insulation as well as enhancement of visual perception by using mainly metalic coating materials.

Properties

Ø adhesive tensile strength: 15 to 40 MPa

Ø porosity: 3 %

Ø layer thickness: 200 to 5.000 µm

Advantages

» possible to spray thickness in excess of 5mm

» increase of service life and decrease of maintenance cost

» ideal for repair of machine parts

» molybdenum wear protection possible

» extremely high economic efficiency

laser cladding:

Surface optimizationby laserdeposition welding.

To extend the life of machines and mechanical equipment, DURIT offers laser deposition welding services - adding preventative, optimized characteristics to tools, parts or components. These surface improvements contribute substantially to minimize wear and reduce cost.

LASER-BASED

COATING PROCESSES

COATING MATERIALS

(Additional coating materials by request)LASER CLADDING

Laser deposition weldingLaser beam powder coating

Laser Cladding

Laser deposition welding

Laser-based coating processes play a key role in today’s manufacturing and maintenance processes. Due to its high accuracy, mostly nickel-cobalt based alloys can be applied very precisely.

Properties

Ø adhesive tensile strength: > 300 MPa

Ø porosity: 0 %

Ø layer thickness: 0.2 to 5 mm and more

Advantages

» very good layer adhesion due to melt-metallurgic bonding

» partial coating as well as complex geometries possible

» high contour definition – even with complex parts and shapes

» creation of very fine microstructures

» limited heat transfer

PVD and CVDCoatings:

Value addedwear optimization

Our process and wear optimized PVD and CVD coatings increase the thermal and chemical resistance of tools and precision parts.

Considerable reduction of friction and adhesive tendencies.

PVD and CVDcoatings.

With PVD and CVD processes you can achieve good wear resistance and high hardness, specifically tailored to each application. Both processes offer a variety of possibilities for targeted improvement of unique material properties with related to i.a.:

» OXIDATION RESISTANCE

» CORROSION RESISTANCE

» BIOCOMPATIBILITY

EXAMPLES OF APPLICATIONS

» Forming, cutting, and punching tools:

Punches, dies, cut-off tools and moveable elements in general

» Injection molds for plastics and light metal alloys:

Mold surfaces, inserts for hot runner systems, ejector pins and other moveable components

» Machining tools:

Milling, drilling and turning tools or insert tips

» Special applications:

engineering components and wear parts i.a. seal faces, valve components, or bearings

COATINGS FOR ALL INDUSTRIES AND APPLICATIONS

PVD| COATING + COLOR | Hardness HV 0.05 | Operating temperature max. in °C | Coefficient of friction | Wear resistance | Features |

|---|---|---|---|---|---|

| HardTiN® | 2600 | 650 | 0.7 | + | good corrosion resistance |

| MegaTiN® | 2800 – 3100 | 1000 | 0.3 | ++ | high hardness and toughness |

| HardTiL® | 3300 | 850 | 0.5 - 0.7 | ++ | good corrosion resistance, good toughness |

| HardTiL ULTRA®® | 3100 – 3300 | 1000 | 0.5 | +++ | high wear resistance |

| HardCrom® | 2700 | 900 | 0.3 - 0.4 | + | very good corrosion resistance |

| HardTiC® | 2700 | 450 | 0.2 - 0.3 | + | low friction coefficient |

| DiExtra® | 2700/1200 | 400 | 0.3 | + | low adhesion |

| DiExtraUltra® | 1470/3000 | 650 | 0.3-0.4 | ++ | very good corrosion resistance |

| DiaPlus® | 3300/1400 | 550 | 0.3 | ++ | very good thermal properties |

| MoldLub® | 2000 | 900 | 0.2 | + | low adhesion |

| DuraLub® | 2800 – 3000 | 600 | 0.3 - 0.4 | ++ | very good thermal properties |

| D-Mold® | 2000 – 2500 | 850 | 0.3 | ++ | low adhesion |

| HardSilk® | 2600 | 1100 | 0.6 | + | very high temperature resistance |

| Galaxy® | 3600 | 1100 | 0.5 - 0.7 | ++ | very high temperature resistance |

| Hardinite® | 3500 – 3700 | 1100 | 0.5 | ++++ | good toughness |

| HardTribo® | 3000 – 4000 | 900 | 0.4 | +++ | good gliding properties |

| UltraImpact® | 2500 –3000 | 1000 -1100 | 0.5 | ++ | very good stability |

| UltraImpact EXCELL® | 2800 - 3000 | 900 | 0.3 - 0.4 | +++ | very high wear resistance, very high gliding properties |

| HardCut® | 4000 | 900 | 0.2 | ++++ | good stability |

CVD

| TiC/TiN | 2700 | 500 | 0.6 | ++ | high toughness |