Laser Cladding

High layer density formore wear protection.

products »

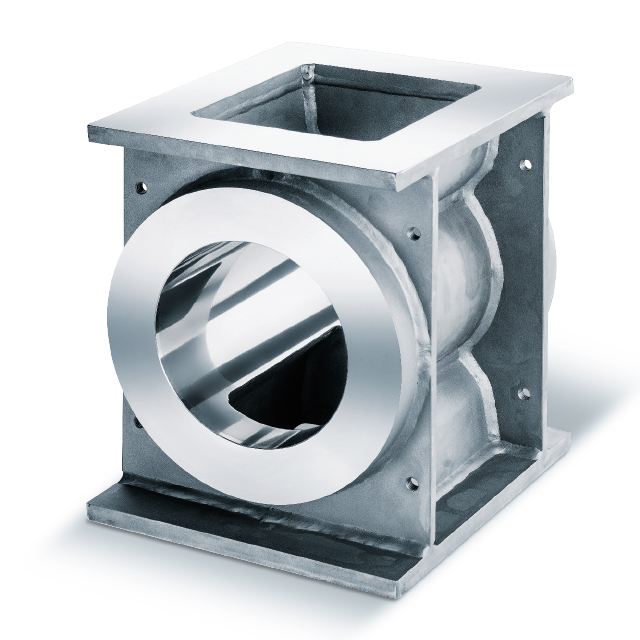

Components for machines such as shafts, guides, rollers, wear strips, etc. Valve components, pump components such as bearings, compressor blades, inner housings, tool elements that require partial wear protection.

typical applications »

The wide range of applications is impressive: a tailor-made coating solution can be found as required. The universal process is suitable for any material that can be melted. This flexibility ensures that a very good result is achieved with the coordinated coating additive: Regardless of whether long-term protection against corrosion, wear or temperature influences is required. Even complex geometries can be produced without any problems. There is also the option of generating strong sandwich structures.