BLAST AND SURFACE TECHNOLOGY

Designed to the Point.Optimized to last.

products »

Nozzles, impeller wheel scoops, linings, accelerators, separators, Impact protection, wear plates, baffles

typical applications »

Surface finishing and cleaning and more

![[Translate to English:] Strahlkabinen Auskleidung Strahl und Oberflaechentechnik DURIT [Translate to English:] Strahlkabinen Auskleidung Strahl und Oberflaechentechnik DURIT](/fileadmin/user_upload/durit/Produkte/Strahl-Oberflaechentechnik/Strahlkabinen-Auskleidung-Strahl-und-Oberflaechentechnik-DURIT.jpg)

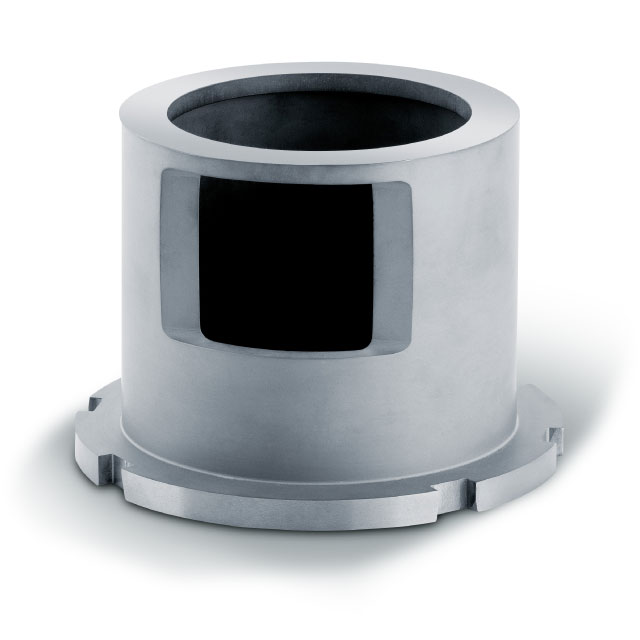

Blasting chamber protection

Distributor sleeve

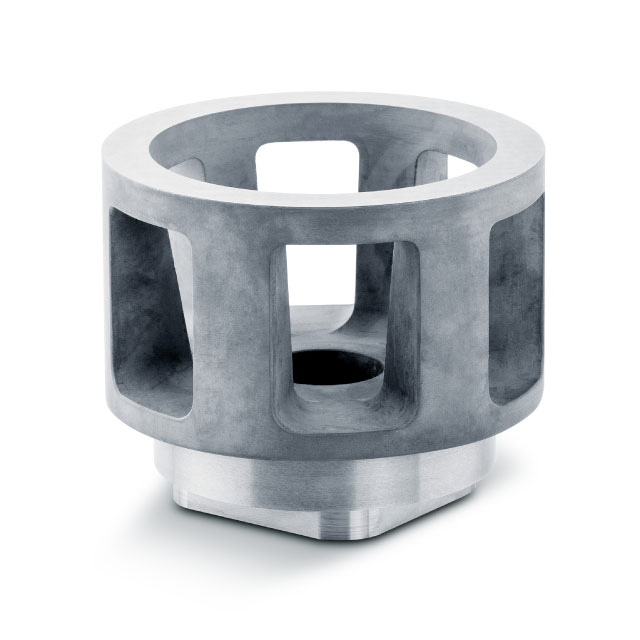

Distributor

Distributor and distributor sleeve

FOR PERFECT RESULTS.

The processing of abrasives puts high demands

on tools and components - carbide meets them.

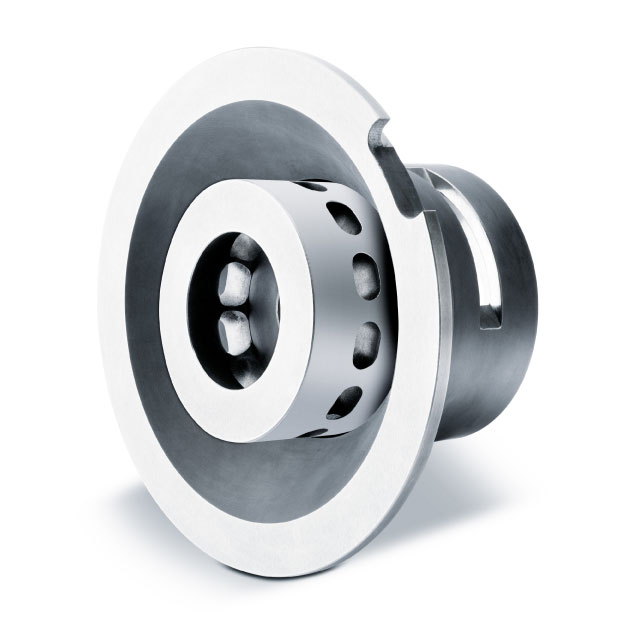

Throw blade

HM equipped throw blade

Throw blade

RADIATING STRENGTH.

Carbide is substantially more fracture-resistant than ceramics, and far more wear and pressure-resistant than steel or other materials.

Inside blasting nozzle

Blasting nozzle

Blasting nozzle