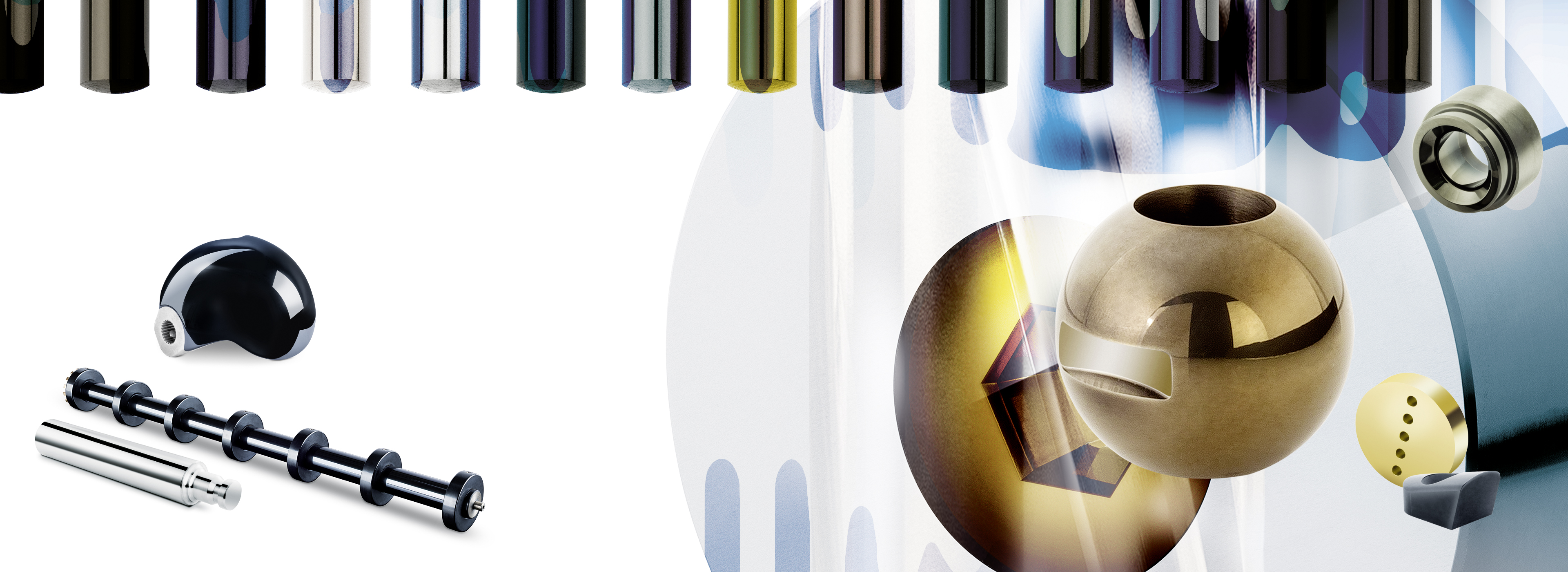

Wear optimizationas a goal.Productivity as a result.

When it comes to minimizing wear, DURIT GLOBAL is one of the companies that lead the way. We also play a leading role in the growing coatings market. Our processes embrace technological innovation and increase performance and service life of parts, tools and components.

More Durability andPerformance

Whats isa coating?

The term “coating” originates in production technology. It describes a main group of production processes per DIN 8580, that are used to apply a FIRMLY ADHERING LAYER OF SHAPELESS MATERIAL to the surface of a tool or workpiece. Fundamentally they are referred to as CHEMICAL, MECHANICAL, THERMAL AND THERMOMECHANICALcoating processes.

COATING PROCESSES CAN BE

DISTINGUISHED TECHNOLOGICALLY

AS FOLLOWS:

according to the original state

of the coating material to be applied

according to the type of carrier material,

or “substrate”

according to the type of adhesive agent,

or “primer”

THE PREVAILING METHOD IS THE

DIFFERENTIATION OF THE ORIGINAL STATE

OF THE COATING MATERIAL TO BE APPLIED:

deposition soldering, deposition welding

Auftragschweißen

Discover ourcoating processes:

» THERMAL SPRAY COATINGS: HVOF, APS, EAWS

» LASER CLADDING

» PVD COATINGS

» CVD COATINGS

Thermalspray coatings

Thermalspray coatings.

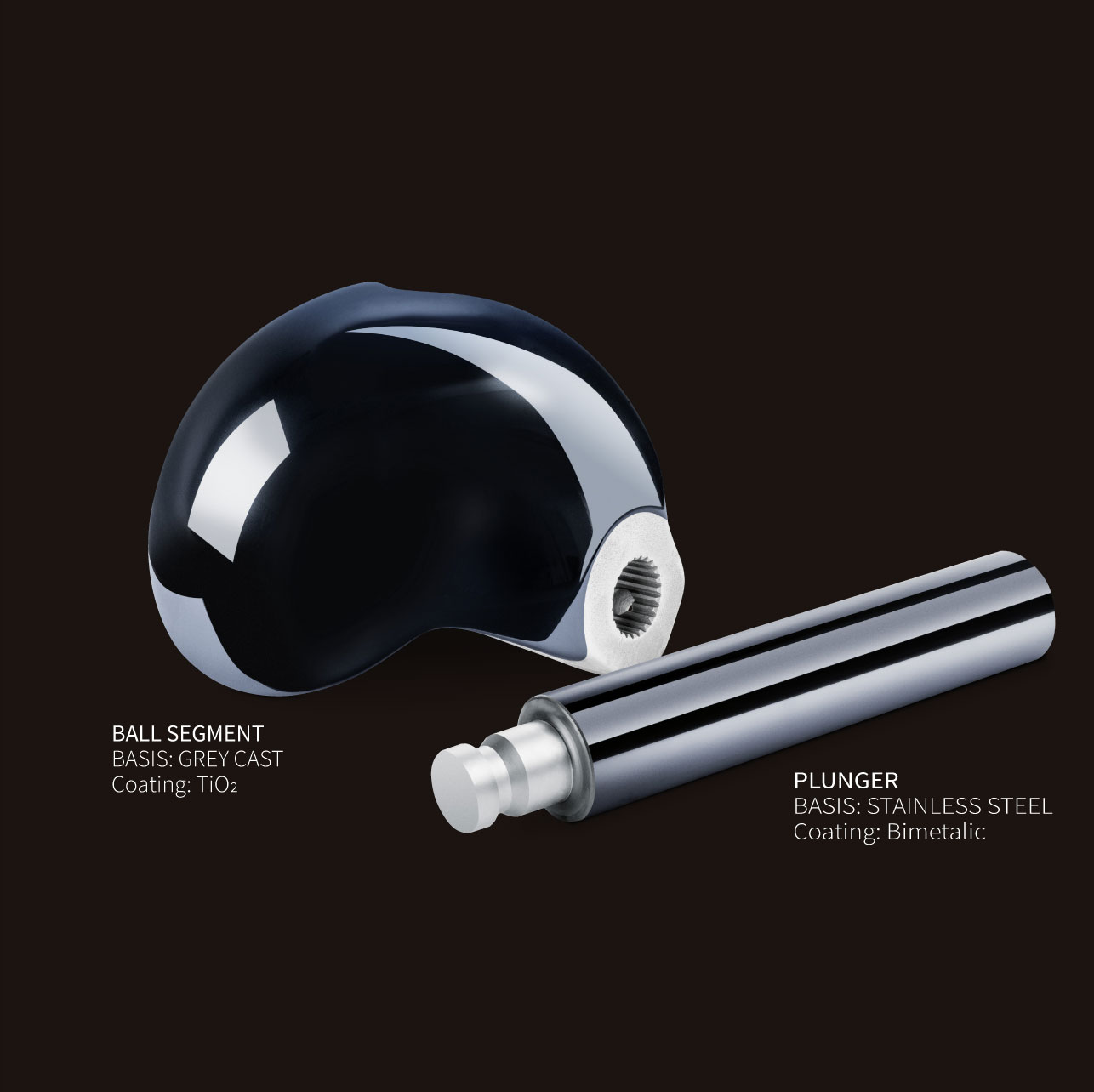

THERMAL SPRAYING is especially effective to equip large parts with a wear-optimized surface. In this process, sophisticated and valuable coating materials, such as carbides, ceramics or metals are applied to the carrier material.

With FLAME SPRAYING PROCESSES, as thermal coatings are often referred to, DURIT creates custom-tailored solutions. To do so, we thoroughly analyze wear tracks and wear patterns as well as failure modes, including all available process and application parameters; such as temperature, pressure, adjacent parts and the process medium. The result: DURIT creates parts, tools and components that are precisely tuned to each unique application. Prior wear problems are specifically targeted, optimized and permanently resolved.

FLAME SPRAY PROCESSES

COATING MATERIALS

(Additional coating materials by request)APS

Atmospheric Plasma Spraying» More » »

CERAMICS

Al2O3TiO2Al2O3/TiO2Cr2O3Cr2O3/TiO2Cr2O3/SiOZrO2/CaOZrO2/MgOZrO/YO/CeOZrO2/Y2O3HVOF –High Velocity Oxi-Fuel

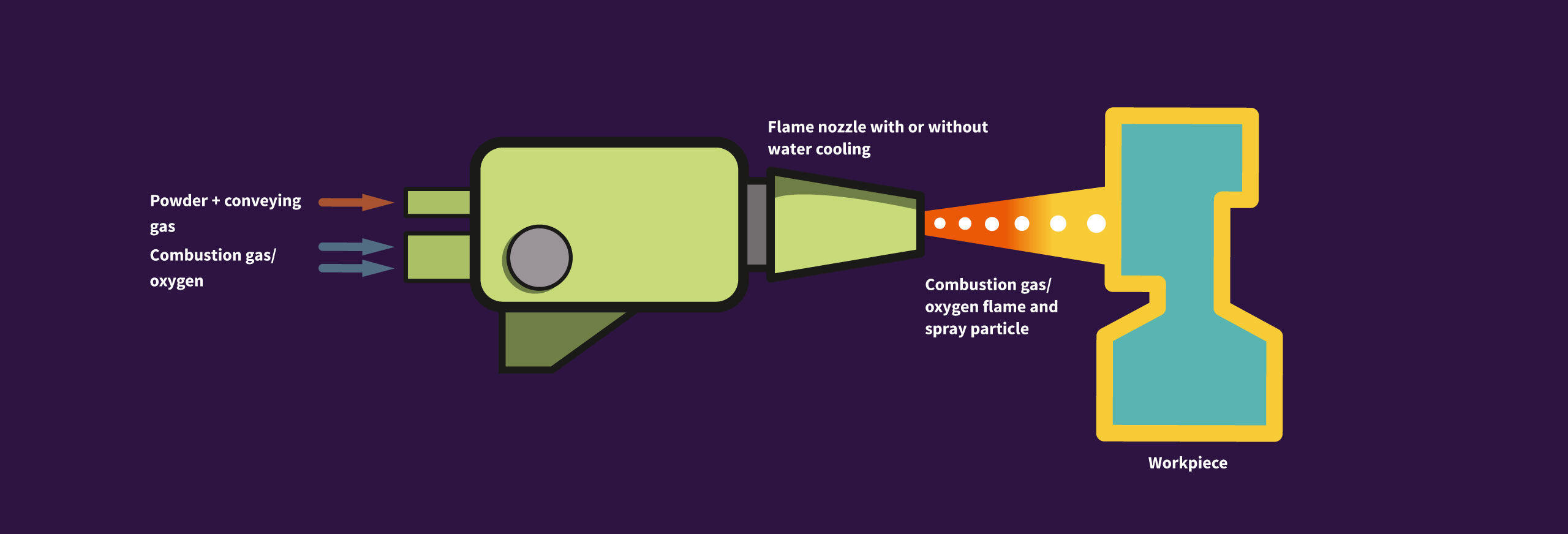

With high-velocity flame spraying a fuel/oxygen mixture is continuously combusted at very high pressure. A powdery spray-additive is injected into the central axis. The pressure created by the gas/oxygen mixture in the combustion chamber and the downstream expansion nozzle create a very high flow velocity. This way the spray particles are accelerated to supersonic speed and applied to the workpiece. Our coating experts are therefore able to apply VERY DENSE LAYERS to enhance the piece with optimal wear properties.

HVOF-Flame Spraying is a high-velocity process, usually applying a CARBIDE OR METAL LAYER, which allows our experts to create DENSELY SEALED surfaces.

HVOFoverview

Properties

Good wear protection against abrasion and erosion, good corrosion resistance, good thermal, electrical or magnetic isolation or increase of conductivity, biocompatibility.

Special technical features

Relatively dense, with a porosity of 0.5 – 1%, therefore gas-tight (diffusion-tight)

Typical applications

Machine parts such as shafts, guides, rollers, wear strips, valve parts, pump parts,

Applicable coating materials

WC/Co, WC/Co-Cr, WC/Ni, WC/NiCr, WC/NiCrBSiFe, Cr2C3/NiCr.

Layer thickness

0,1–0,5 mm.

Amount of coating per hour

2,5–3,0 kg

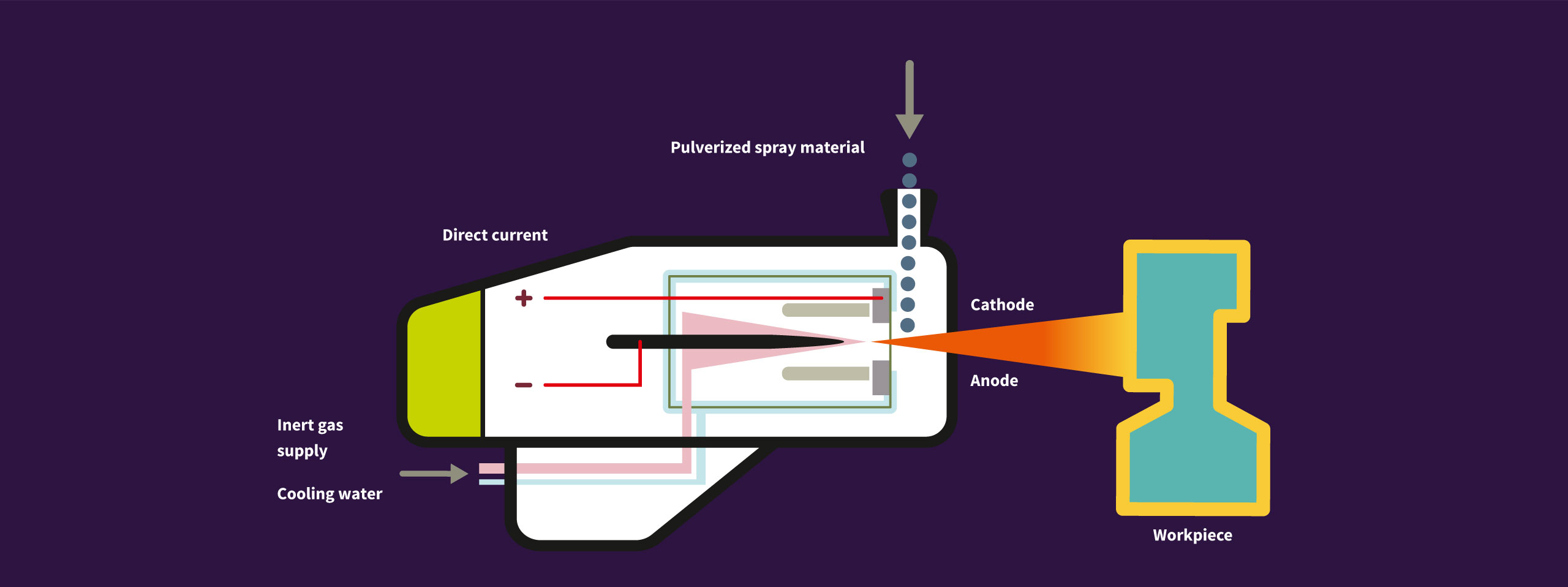

APS –Atmospheric Plasma Spraying

With the APS process, or “plasma spraying”, the powdery spray-additive is melted inside or outside the spray gun by a plasma beam and flung onto the surface of the workpiece. The most flexible of all thermal spray processes allows excellent handling and control to create optimal layer thicknesses and surface properties with regard to porosity and hardness.

APSoverview

Properties

Good wear protection against abrasion and erosion, good corrosion resistance, good thermal, electrical or magnetic isolation, biocompatibility.

Special technical features

Relatively porous, with a porosity of 4 – 8%, therefore not gas-tight or diffusion-tight

Typical applications

Valve inserts, pump parts (e.g. bearing housings), pistons especially with chemical demands

Applicable coating materials

Ceramics like Al2O3, TiO2, Al2O3/TiO2, Cr2O3, Cr2O3/TiO2, Cr2O3/SiO, ZrO2/CaO, ZrO2/MgO, ZrO/YO/CeO, ZrO2/Y2O3.

Layer thickness

0.2 – 0.5 mm (in middle sometimes up to 1 mm possible)

Amount of coating per hour

2,5–3,5 kg.

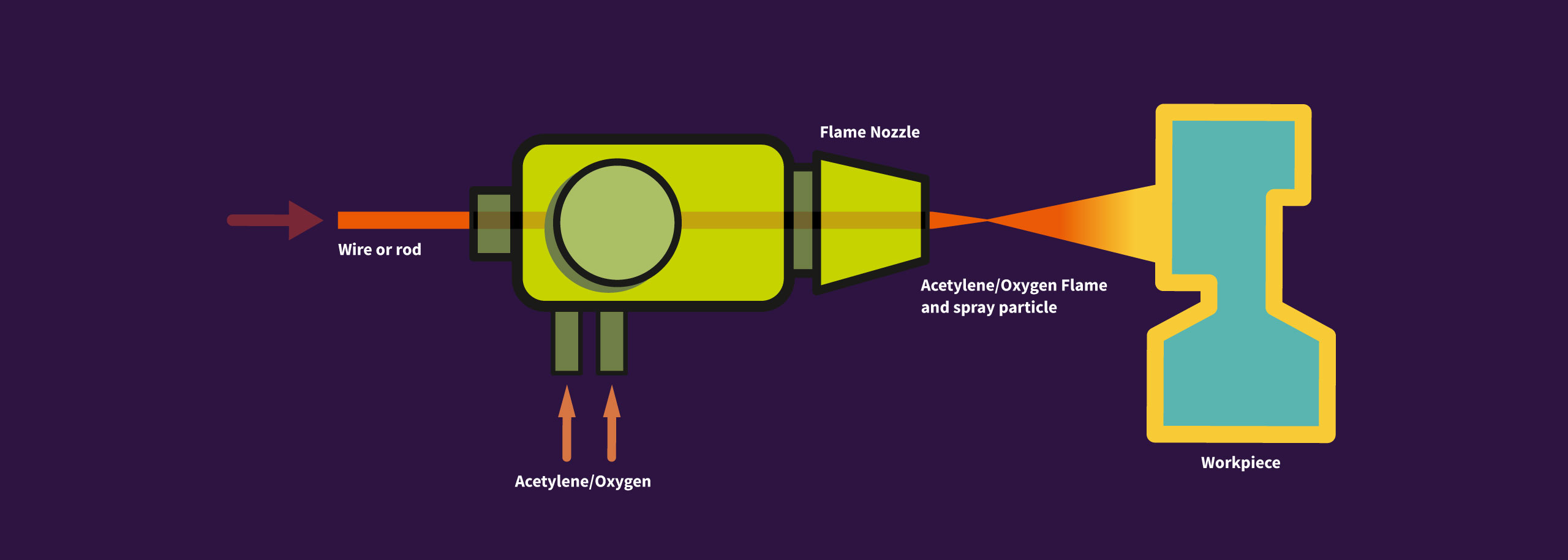

EAWS –electric arc wire spraying

With electric ARC wire spraying the spray additive is continually melted in the center of an acetylene/oxygen flame. Aided by a vaporizer gas, i.e. compressed air or nitrogen, droplet-shaped spray particles are separated and flung onto the primed surface of the workpiece. This process allows high spray rateswith low gas consumption. EAWS creates surface layers with an average porosity of about 3% and an adhesive pull strength of 40 MPa for greatly increased wear protection.

EAWSoverview

Properties

Good wear protection against abrasion and erosion, good corrosion resistance, good thermal, electrical or magnetic isolation or increase in conductivity, biocompatibility.

Special technical features

Relatively porous, with a porosity of 4 – 8%, therefore not gas-tight or diffusion-tight

Typical applications

Machine parts such as shafts, guides etc., valve parts

Applicable coating materials

Metals such as Mo99.9+, Cu5Al, Ni20Cr, Sn7, 5Sb3,5Cu, AISI420, AISI316, AISI304

Liga C-276, stainless steels

Layer thickness

0.2 – 0.8 mm (in middle sometimes up to 5 mm possible)

Amount of coating per hour

10–20 kg.

Laser CladdingLaser technology coating processes

LASER TECHNOLOGY

COATING PROCESSES

THE COATING MATERIALS

(Additional coating material by request)LASER CLADDING

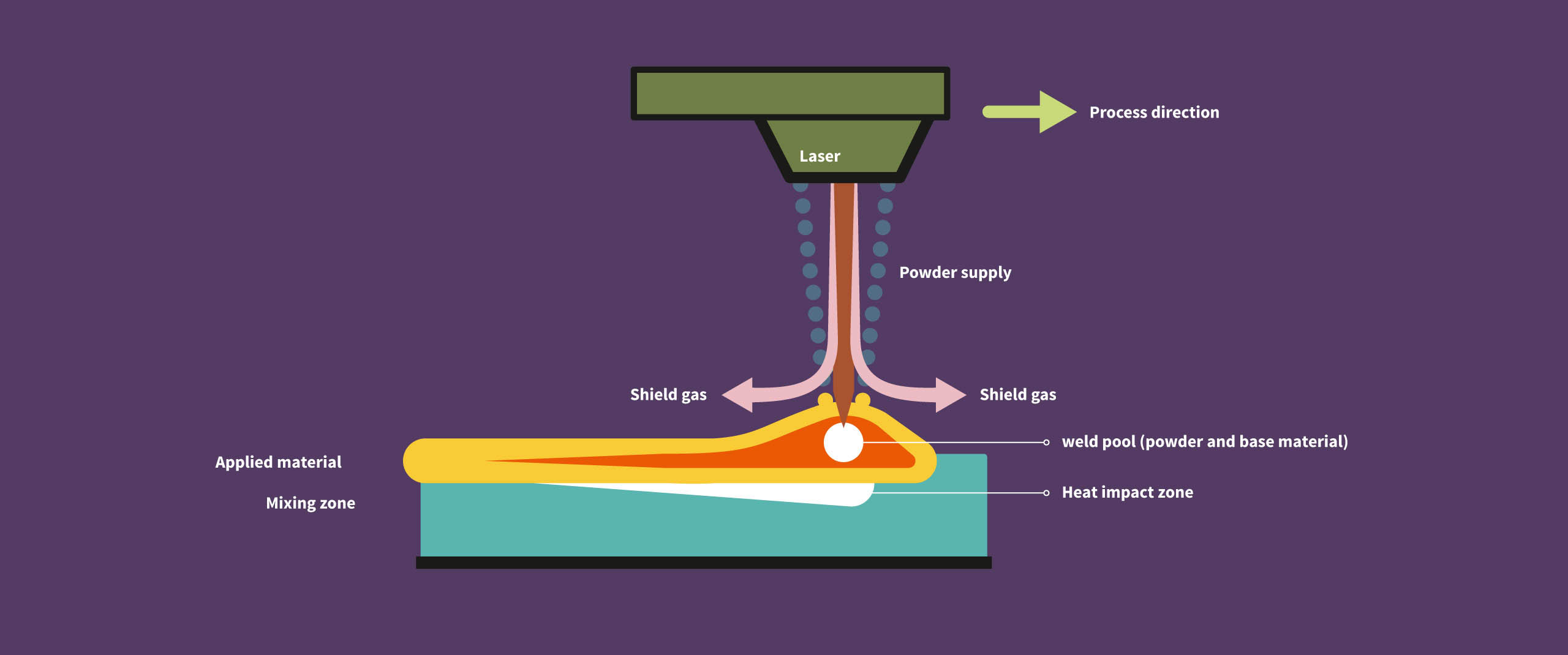

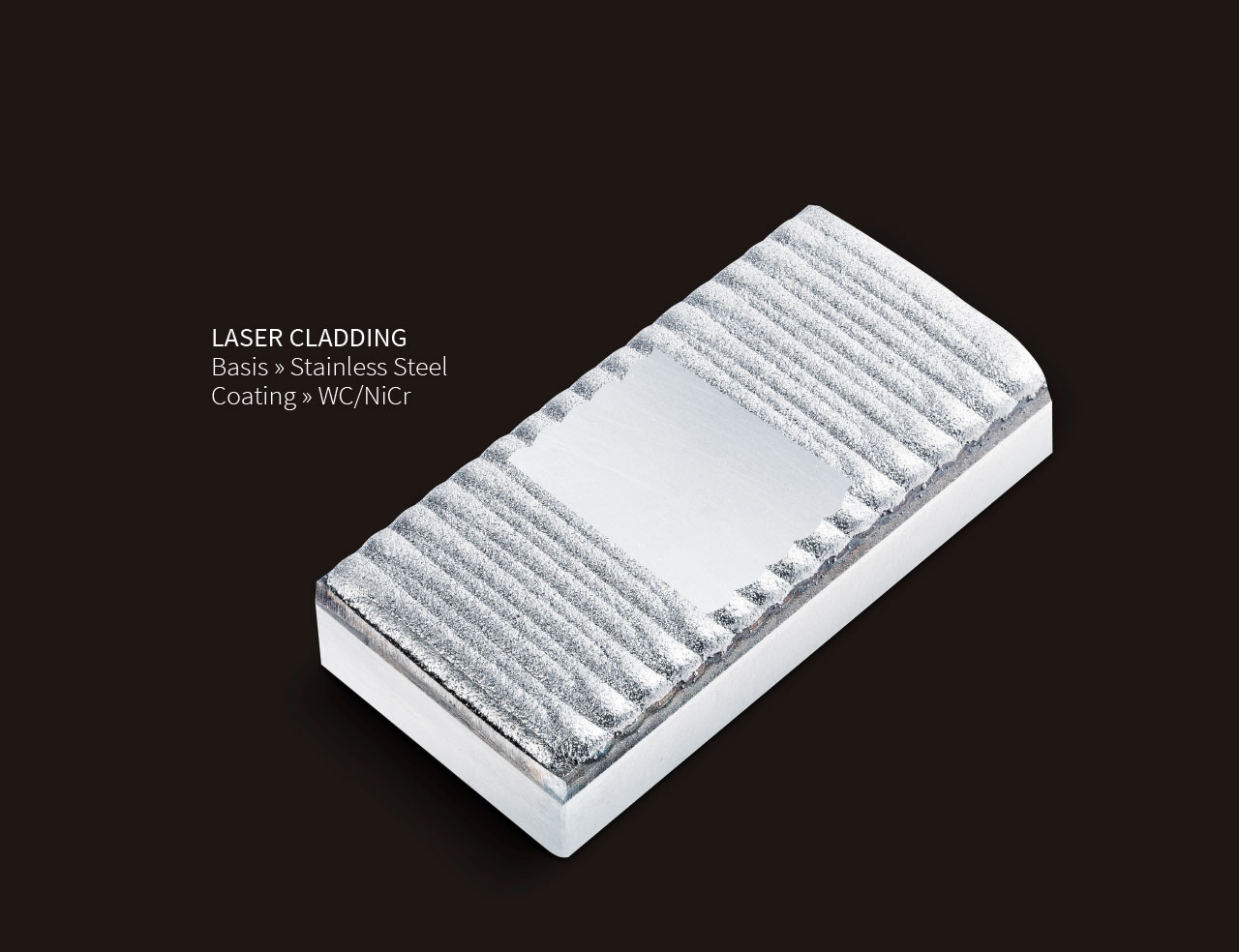

Laser claddingLaser-beam powder coating

Laser cladding

With laser cladding per DIN 8590 the surface of the workpiece is melted locally. Motion of the laser optics and powder nozzle create weld-beads on the workpiece to be coated. The laser creates a weld pool on its surface. Metal powder is automatically inserted through a nozzle. Applied side-by-side, defined areas can be functionally coated and applied on top of each other to increase layer thickness so that part shapes can be created or repaired.

Laser claddingoverview

Properties

Very good layer adhesion due to molten metal bonding, partial coating as well as complex geometries possible, precise line detail with elaborate part shapes, development of very fine micro-structures, limited heat transfer. Very high adhesive pull strength.

Special technical features

Completely sealed surface, with a porosity of 0%, therefore gas-tight or diffusion-tight. Very high adhesive pull strength.

Typical applications

Machine parts such as shafts, guides, rollers, wear strips etc., valve parts, pump parts such as bearings, compressor blades, housing interiors that require partial wear protection

Applicable coating materials

All meltable metals in powder form such as Inconel, Hastelloy, Stellite etc. as well as carbides with different binders.

Layer thickness

0.2 – 5 mm and more

PVD- und CVD-coatings

PVD- and CVD-coatings

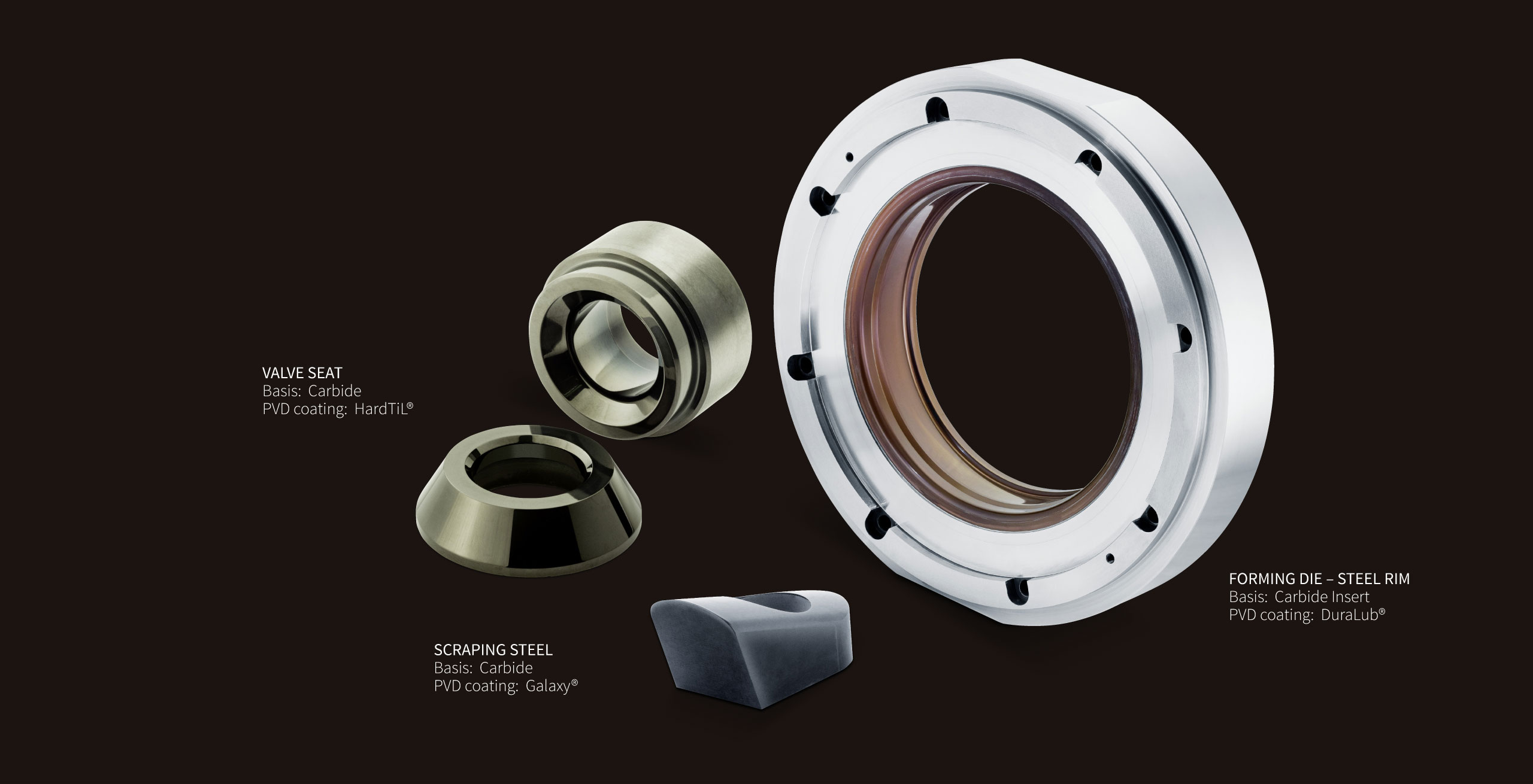

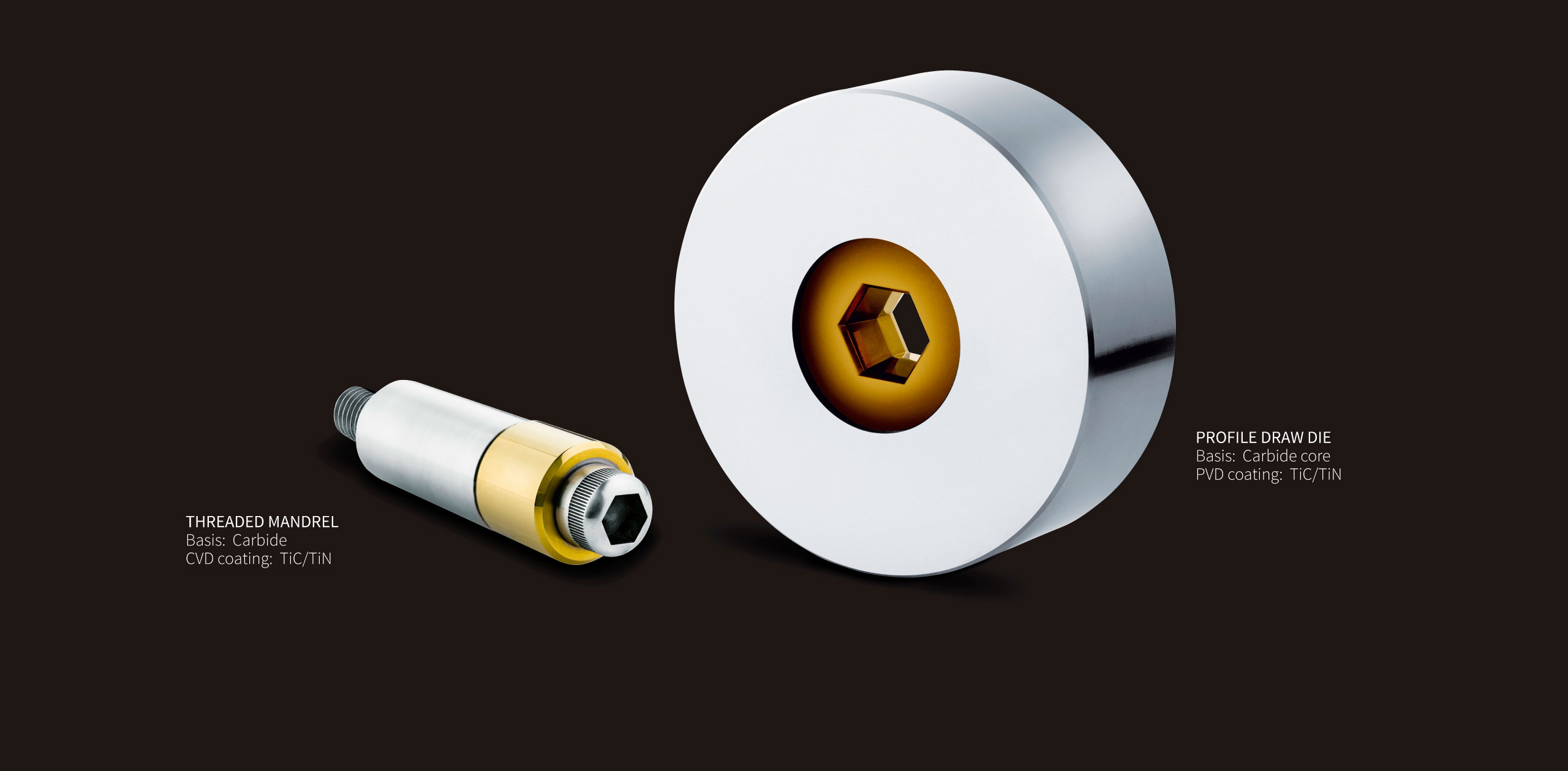

PVD and CVD processes are frequently used with metal cutting and shaping tools – especially to increase service life.

The differing methods have an impact on the ability to coat the tools.

With PVD and CVD processes - specifically tailored to the respective application - GOOD WEAR RESISTANCE AND HIGH HARDNESS can be achieved. Both processes offer a wide range of options for successfully improving individual material properties with regard to:

» OXIDATION RESISTANCE

» CORROSION RESISTANCE

» BIOCOMPATIBILITY

COATINGS FOR ALL INDUSTRIES AND APPLICATIONS

PVD| COATING + COLOR | Hardness HV 0,05 | Operating temperature max. in °C | Coefficient of friction | Wear resistance | Features |

|---|---|---|---|---|---|

| HardTiN® | 2600 | 650 | 0,7 | + | good corrosion resistance |

| MegaTiN® | 2800 – 3100 | 1000 | 0,3 | ++ | high hardness and toughness |

| HardTiL® | 3300 | 850 | 0,5 - 0,7 | ++ | good corrosion resistance, good toughness |

| HardTiL ULTRA®® | 3100 – 3300 | 1000 | 0,5 | +++ | high wear resistance |

| HardCrom® | 2700 | 900 | 0,3 - 0,4 | + | very good corrosion resistance |

| HardTiC® | 2700 | 450 | 0,2 - 0,3 | + | low friction coefficient |

| DiExtra® | 2700/1200 | 400 | 0,3 | + | low adhesion |

| DiExtraUltra® | 1470/3000 | 650 | 0,3-0,4 | ++ | very good corrosion resistance |

| DiaPlus® | 3300/1400 | 550 | 0,3 | ++ | very good thermal properties |

| MoldLub® | 2000 | 900 | 0,2 | + | low adhesion |

| DuraLub® | 2800 – 3000 | 600 | 0,3 - 0,4 | ++ | very good thermal properties |

| D-Mold® | 2000 – 2500 | 850 | 0,3 | ++ | low adhesion |

| HardSilk® | 2600 | 1100 | 0,6 | + | very high temperature resistance |

| Galaxy® | 3600 | 1100 | 0,5 - 0,7 | ++ | very high temperature resistance |

| Hardinite® | 3500 – 3700 | 1100 | 0,5 | ++++ | good toughness |

| HardTribo® | 3000 – 4000 | 900 | 0,4 | +++ | good gliding properties |

| UltraImpact® | 2500 –3000 | 1000 -1100 | 0,5 | ++ | very good stability |

| UltraImpact EXCELL® | 2800 - 3000 | 900 | 0,3 - 0,4 | +++ | very high wear resistance, very high gliding properties |

| HardCut® | 4000 | 900 | 0,2 | ++++ | good stability |

CVD

| TiC/TiN | 2700 | 500 | 0,6 | ++ | high toughness |

COATINGSFor more durability

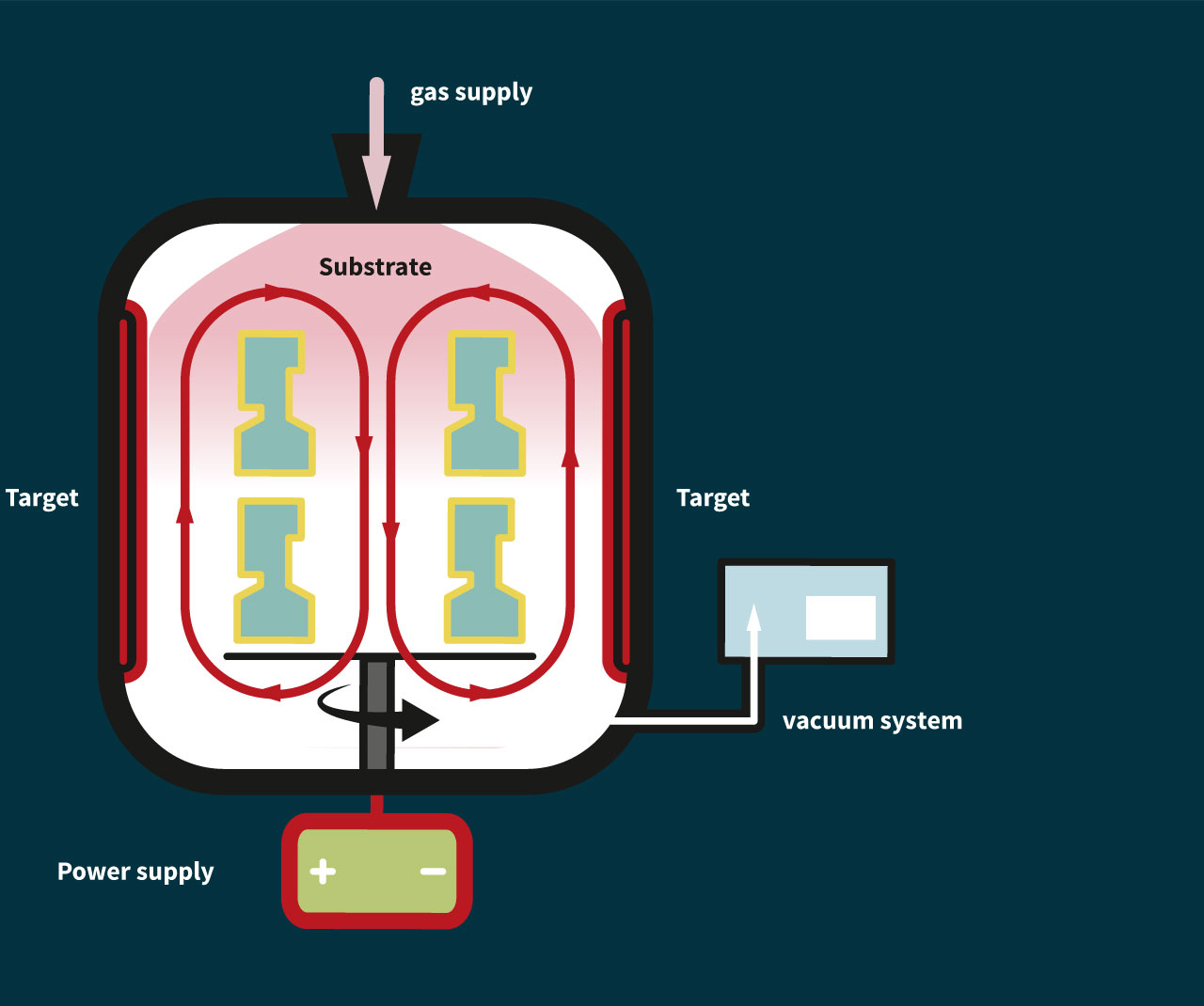

PVD –physicalvapourdeposition

The PVD process is based on the release of metallic layer components such as titanium, aluminum, zirconium or chromium. They are transformed into their gaseous state using a full vacuum and their particles are transported towards the workpiece through electrical currents and plasma. By adding a reactive component, such as nitrogen or carbon, they attach firmly to the surface.

The PVD process enables the separation of Very thin, yet also very hard firmly adhering layers

The most common are: titanium-nitride coatings, titanium-aluminum-nitride coatings, chromium-nitride coatings as well as titanium-carbide coatings.

All PVD coatings made by DURIT deliver convincing performance with their outstanding adhesive qualities. DURIT PVD coatings minimize wear permanently.

PVD-COATINGPROCESS

The coating material, also known as target, is vaporized in a vacuum chamber using a plasma in a so-called sputter or laser ARC process. The gas created spreads out as a fine mist within the chamber and finally condenses on the workpieces to be coated.

PVDOVERVIEW

Properties

Good glide capacity, low friction coefficient, high hardness and corrosion resistance.

Special technical features

Bores are only completely coated to a depth of 1 x D. At lower depths, layer thickness decreases.

Materials to be coated

All metals, ceramics, plastics, glass.

Layer thickness

3 – 5 µm. Thicker layers can be created, but tend to develop cracks due to higher internal stress.

Coating temperatures

450°C or lower (up to 180°C), which allows coating of collared tools. Soldered parts can also be coated, but a special solder must be used.

Maximum part size

Ø 400 x 800 mm, up to max. 250 kg

Typical Applications

Drawing tools:

Reduction of friction, protection from aggressive mediums

Punching tools:

Increased stability of cutting edge, protective layer to avoid galling

Shaping tools:

Reduction of friction, protective layer to avoid galling

Bearing sleeves:

Reduction of friction, protection from aggressive mediums, biocompatibility

Cutting tools:

Increased stability of cutting edge, reduction of friction

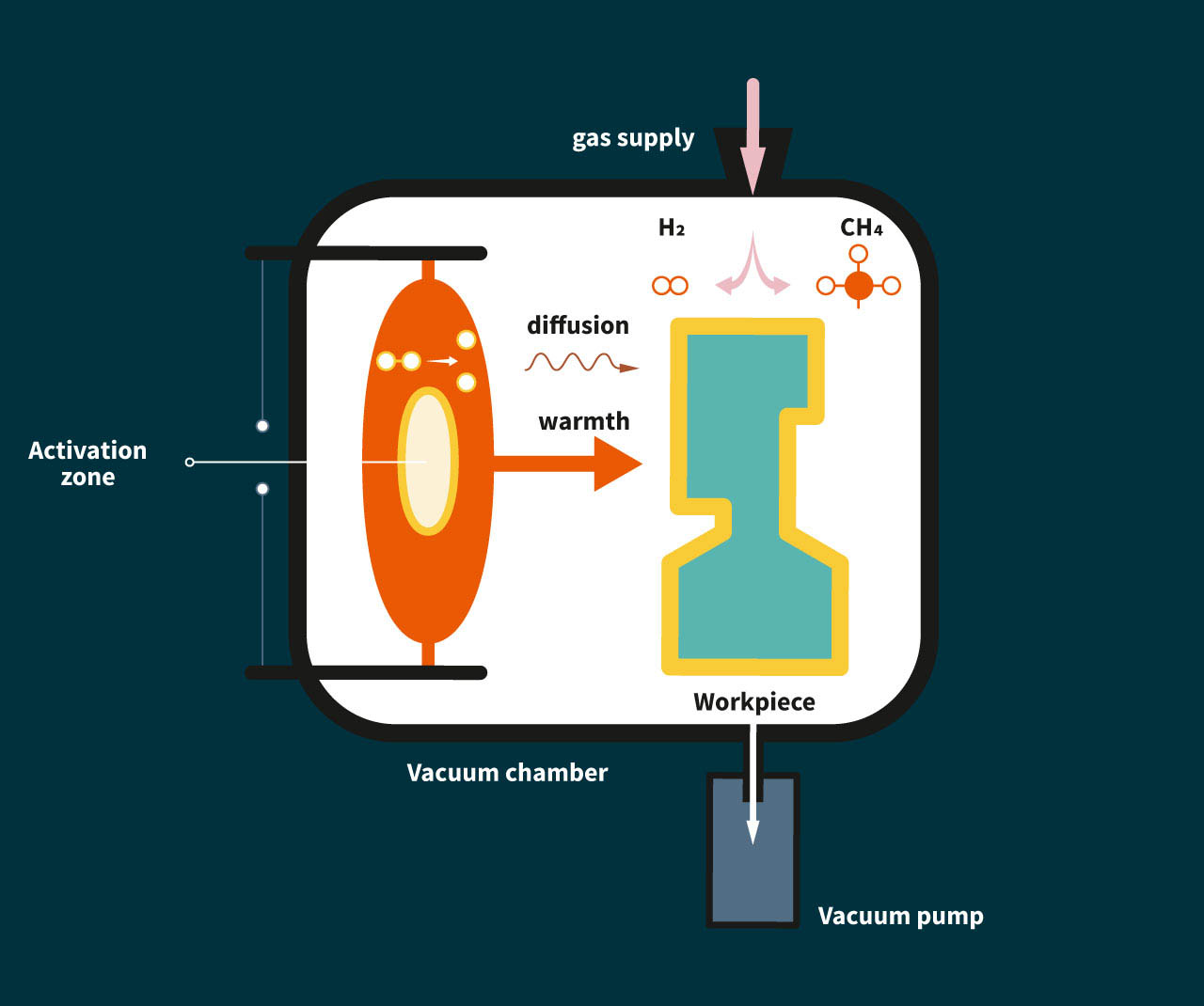

CVD –chemicalvapourdeposition

At temperatures of about 1,000°C the layer components flow around the tool and react with elements of the substrate surface. The layer systems (TiC, TiN/TiC or TiC/TiN) have an average thickness of 7 – 10 µm.

The CVD process can be described as the formation of a thin, firm film that develops from deposits of the gaseous material. This substance is created by the chemical decomposition of a solid. The resulting coatings have very high wear resistance and excellent adhesion.

The first CVD coated carbide was the single-layer titanium-carbide coating (TiC). Titanium-nitride (TiN) coatings and TiC/TiN coatings followed sometime later. Due to the chemical process of this method coating of bores and undercuts are possible.

CVD-COATINGPROCESS

From the heated surface of a substrate a solid component is separated through a chemical reaction in the gas phase. This takes place in a vacuum chamber. The gas created spreads out as a fine mist within the chamber and finally condenses on the workpieces to be coated. Due to the stress distribution and particle size the smallest contours and shapes can be coated.

CVDOVERVIEW

Properties

Good glide capacity, low friction coefficient, high hardness.

Special technical features

Bores are completely coated, meaning complete layer thickness throughout the entire bore depth, very good adhesion to the substrate.

Materials to be coated

All temperature resistant metals, ceramics.

Layer thickness

7 – 12 µm. Even thicker layers can be created, but tend to develop cracks due to higher internal stress.

Coating temperatures

At over 1,000°C armored tools can no longer be coated. Only solid, single parts can be coated. A special case are hardened steels – their hardening takes place at the same time as the coating.

Maximum part size

Ø 600 x 800 mm, up to max. 330 kg

Typical Applications

Drawing tools:

Reduction of friction, protection from aggressive mediums

Punching tools:

Avoid galling

Shaping tools:

Reduction of friction, protective layer to avoid galling

Cutting tools:

Reduction of friction

ACCOMPLISH MORE:WITH EFFECTIVECOATINGS BY DURIT

We are looking forward to taking the time and speaking with you in person. Our design and technical sales teams will certainly find the best solution against wear for your tool, part or component. Our coating experts appreciate your call. Or simply send us an email to:

» » » info@durit.de